The Truth About MOQs

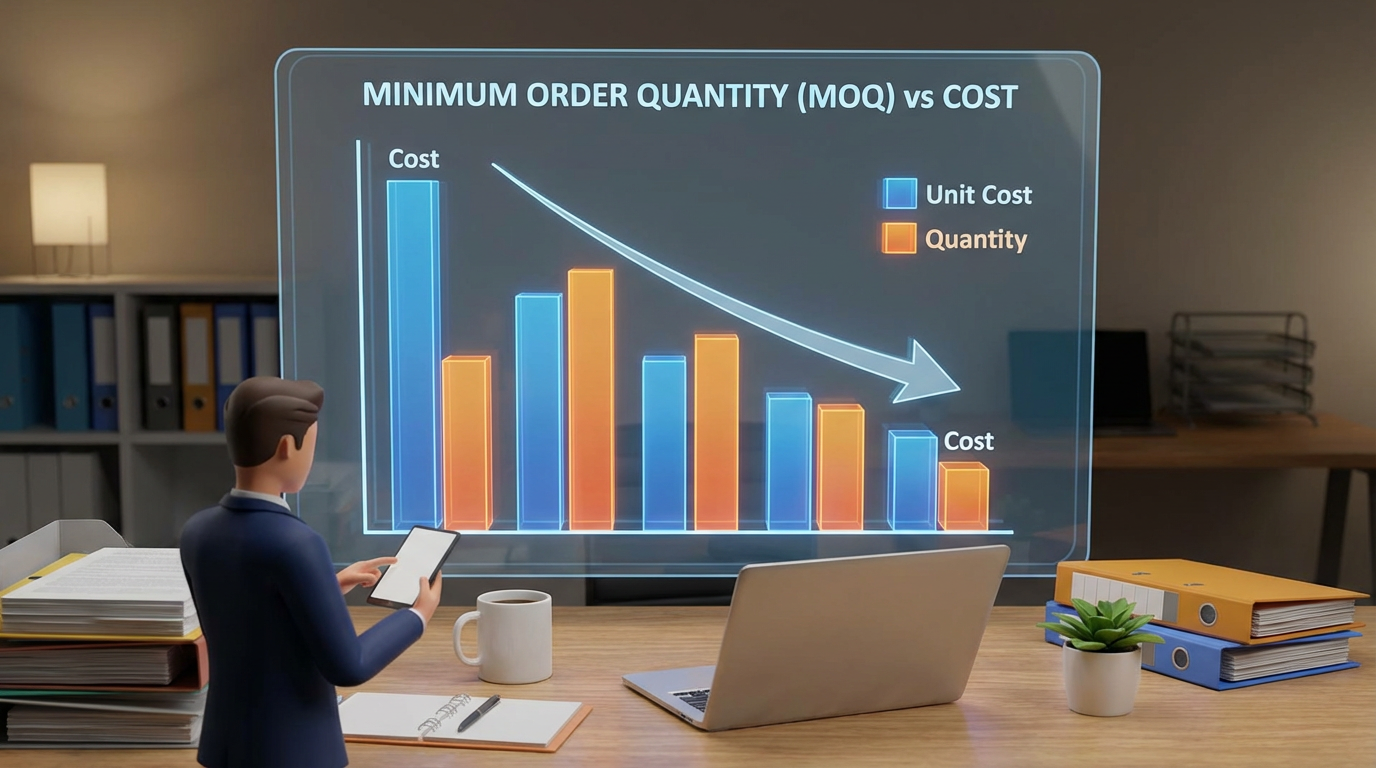

Minimum Order Quantity (MOQ) is a term every procurement manager knows well. In the custom stationery world, MOQs exist because setting up machines for customization takes time and money.

Why MOQs Exist

- Setup Costs: Creating a metal mold for a custom pen clip or a copper die for logo debossing costs the same whether you make 10 units or 10,000.

- Material Waste: Calibrating machines consumes material.

- Efficiency: Production lines run smoothest when uninterrupted.

Standard MOQs at StationeryWorks

- Ready Stock with Logo: Usually 50-100 units. We take existing stock and print/engrave it locally in KL. Fast, but slightly higher unit cost.

- Fully Custom Orders: Usually 500-1,000 units. This allows for custom Pantone covers, custom inner pages, and unique accessories. Lower unit cost, longer lead time.

Strategies to Optimize

- Consolidate Departments: Instead of HR ordering 200 notebooks and Sales ordering 300, combine them into a 500-unit order to unlock better pricing and customization options.

- Annual Forecasting: Order for the whole year. We can often offer warehousing solutions, delivering in batches while you pay the bulk price.

- Generic vs. Specific: Keep the main item generic (Company Logo) and use packaging or belly bands to customize for specific events.

Planning a large order for a government contract? Read our guide on Sourcing for Government Tenders.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.

Share this article: