In the realm of high-precision corporate stationery manufacturing, the choice between UV LED printing and fiber laser engraving is not merely aesthetic—it is a fundamental engineering decision that dictates the longevity, tactile experience, and brand perception of the final product. As a material engineer specializing in surface finishing for anodized aluminum and stainless steel writing instruments, I have conducted extensive durability tests to demystify these two dominant technologies.

The Physics of Surface Modification

Laser engraving, specifically using a 1064nm Fiber Laser, operates on the principle of ablation. The high-intensity beam vaporizes the surface layer of the material—typically the dyed anodic coating on aluminum pens—to reveal the raw base metal underneath. This process creates a permanent, physical indentation that is impervious to chemical solvents or mechanical abrasion. The depth of the engraving can be controlled with micron-level precision, allowing for tactile relief that adds a dimension of luxury.

Conversely, UV printing utilizes photopolymerizable inks that cure instantly when exposed to ultraviolet light. The print head deposits microscopic droplets of ink, which are then 'frozen' in place by UV LED lamps. This forms a polymer layer on top of the substrate. While modern adhesion promoters have significantly improved the bond strength on metals, the marking remains an additive process. It sits on the surface rather than being part of it.

Durability Under Stress: The Cross-Hatch Test

To evaluate the resilience of both methods, we subjected samples to the ASTM D3359 cross-hatch adhesion test and a custom tumble abrasion cycle simulating two years of daily use in a pocket or bag. The laser-engraved samples showed zero degradation, as the marking is intrinsic to the material. The UV-printed samples, while robust, eventually showed signs of micro-chipping at the edges of the logo after 500 tumble cycles, particularly on sharp corners where the ink film is most vulnerable to shear forces.

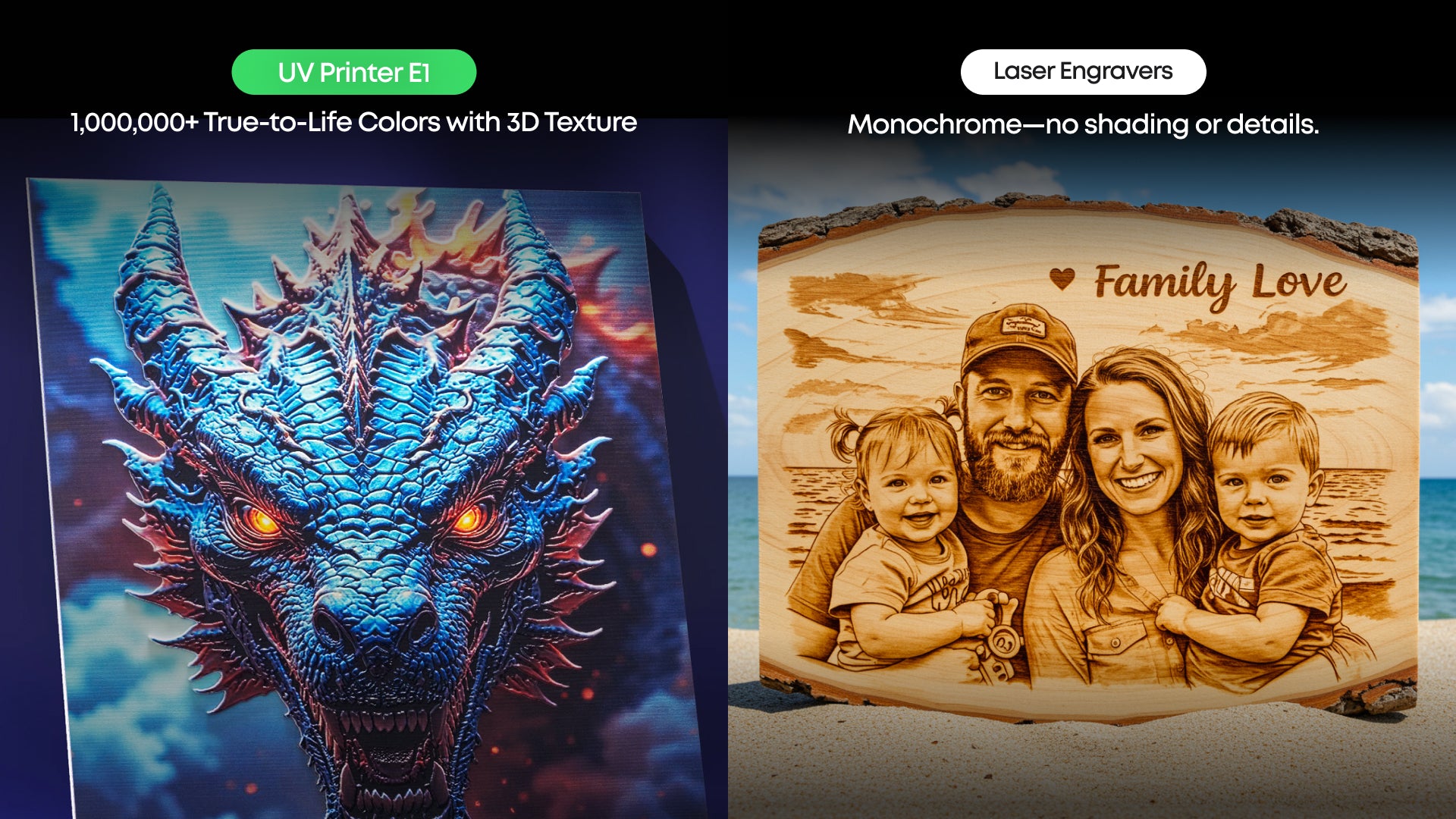

However, UV printing holds a distinct advantage in color reproduction. Laser engraving on metal is generally monochromatic—silver or gold depending on the base metal (brass or aluminum). UV printing allows for full CMYK color gamuts, enabling the reproduction of complex corporate gradients and Pantone-matched logos. For brands where color fidelity is non-negotiable, UV printing is the only viable engineering solution, provided a primer is applied to ensure chemical bonding.

Production Efficiency and Environmental Impact

From a manufacturing workflow perspective, laser engraving is a dry, non-contact process that requires no consumables other than electricity. It produces no volatile organic compounds (VOCs), making it a cleaner option for ISO 14001 certified facilities. UV printing, while low-VOC compared to solvent inks, still involves chemical handling and ink waste disposal. The energy consumption of UV LED curing systems has dropped significantly, but laser systems remain the benchmark for energy efficiency in high-volume production runs.

Strategic Application for Corporate Identity

When advising clients on the optimal technology, I analyze the intended lifecycle of the product. For executive gifts intended to last a decade, the permanence of laser engraving is unmatched. It communicates stability and endurance. For promotional campaigns requiring vibrant visual impact and shorter lifecycles, UV printing offers the versatility to capture attention. Understanding these material science nuances ensures that the chosen method aligns perfectly with the brand's engineering standards and aesthetic goals.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.