When specifying the decoration method for canvas tote bags, the decision often boils down to two contenders: traditional screen printing and digital heat transfer. As a textile engineer with over 15 years in fabric finishing, I approach this choice by analyzing the interaction between the ink matrix and the fiber structure of the canvas. The goal is to balance visual fidelity with mechanical durability.

Screen Printing: The Penetration Advantage

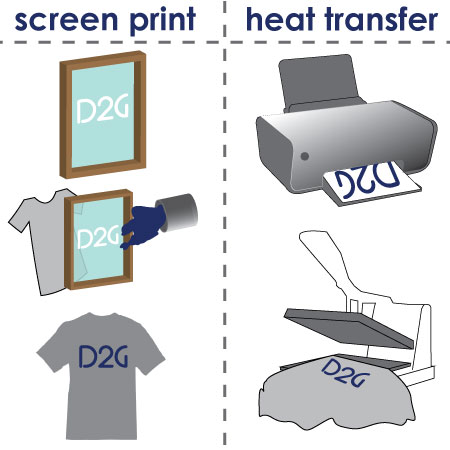

Screen printing, particularly when using water-based or discharge inks, relies on driving the pigment into the fabric weave. The squeegee pressure forces the ink through the mesh and into the interstices of the cotton fibers. This mechanical interlocking creates a print that moves with the fabric. On heavy 12oz canvas, this is crucial. The ink becomes part of the textile structure rather than a surface film.

For corporate logos requiring specific Pantone matches, we often use plastisol inks. While these sit more on the surface, they offer opacity that water-based inks struggle to achieve on dark fabrics. The trade-off is the 'hand-feel'—a heavy plastisol print can feel rubbery and stiff. To mitigate this, we employ high-mesh screens (up to 120T) to deposit a thinner, more controlled ink layer, followed by a flash cure and a final heat tunnel cure at 160°C to ensure full polymerization.

Heat Transfer: The Resolution Revolution

Digital heat transfer (DTF or Direct-to-Film) has revolutionized the industry by allowing for photorealistic images and complex gradients that are impossible with screen printing. The process involves printing the image onto a PET film, applying a hot-melt powder adhesive, and then heat-pressing it onto the canvas. The adhesive melts and bonds to the surface fibers.

From an engineering standpoint, the weak link in heat transfer is the adhesive layer. It forms a continuous film that can crack over time if the canvas stretches significantly. However, modern polyurethane (PU) based transfers have excellent elasticity and rebound properties. They can withstand 50+ industrial wash cycles without delamination, provided the application temperature and pressure were optimized during production.

The Economics of Scale and Complexity

The choice is often dictated by the complexity of the artwork and the volume of the order. Screen printing requires a separate screen for each color. The setup time and cost are high, making it inefficient for small runs or multi-color designs. However, for a simple 1-color logo on 1000 bags, it is the most cost-effective and durable method.

Heat transfer, being a digital process, has zero setup cost per color. It is ideal for full-color designs or variable data (like individual names) on smaller batches. However, the unit cost remains constant regardless of volume, making it expensive for large runs.

Breathability and Utility

One often overlooked factor is breathability. A large heat transfer patch acts as a plastic barrier, reducing the breathability of the canvas. For a tote bag, this is less critical than for a t-shirt, but it still affects the drape and folding of the bag. Screen printing, especially with water-based inks, maintains the fabric's natural breathability and flexibility. For premium corporate gifts where the tactile quality is paramount, I almost always recommend screen printing for its superior integration with the base material.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.