In corporate procurement, we often treat "Sampling Time" as a static variable in our Gantt charts. We allocate 7 days for it, assuming that on Day 7, we will have a perfect sample in hand, ready to sign off.

As a Quality & Compliance Consultant, I see this assumption fail more often than it succeeds. The reality is that sampling is not a linear step; it is a conditional loop.

The Mathematics of the "Rejection Loop"

When a supplier quotes "7 Days for Sampling," they mean "7 Days for the First Sample." They do not account for the probability of rejection.

If the first sample arrives and the Pantone color is slightly off (a Delta E > 3.0 variance), or the logo position is 5mm too low, you cannot approve it. You must reject it.

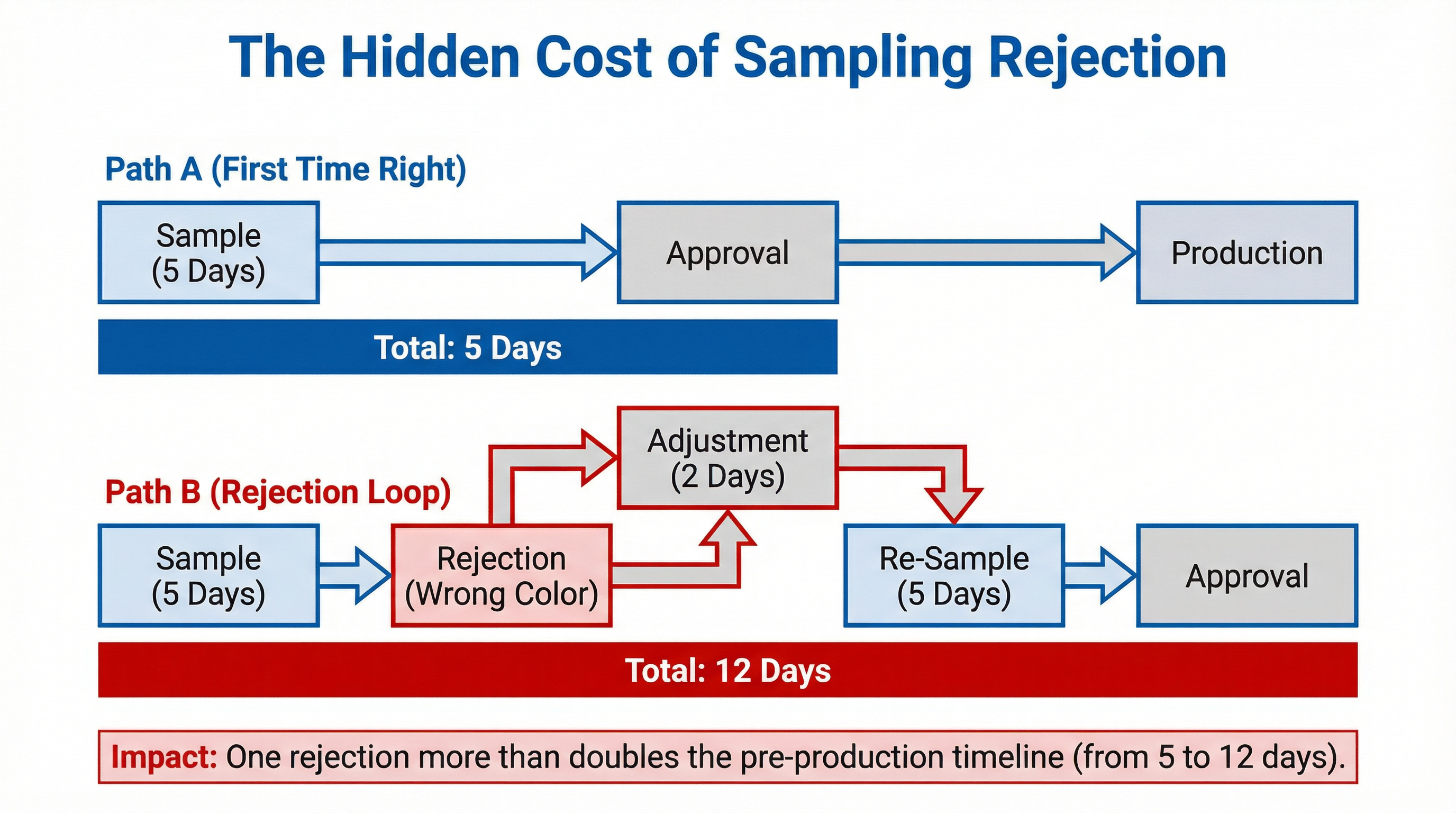

Here is where the timeline explodes:

- Feedback Transmission (1 Day): You compile photos and explain the defect.

- Adjustment (2-3 Days): The factory has to re-mix the ink or re-calibrate the machine.

- Re-Sampling (5-7 Days): They have to run the sample again.

- Shipping (1-2 Days): The new sample travels to your office.

Suddenly, a "minor adjustment" has added 10+ days to your timeline. If this happens twice, your 7-day buffer becomes a month-long delay.

[Image blocked: Diagram comparing a 'First Time Right' timeline (5 days) vs. a 'Rejection Loop' timeline (12+ days), showing how one rejection doubles the time.]

Why "Digital Proofs" Are Not Enough

Many procurement teams try to skip physical sampling to save time, relying on digital mockups (E-Proofs) instead. While this works for simple layouts, it is a gamble for physical attributes.

- Texture & Hand-Feel: A digital PDF cannot show you that the "Soft Touch" coating feels sticky in Malaysia's humidity.

- Weight: A photo cannot tell you that the "Metal Pen" feels like hollow plastic.

- Color on Material: Pantone 286C looks different on a white paper notebook versus a black PU leather cover.

Skipping the physical sample to save 7 days often leads to a "Mass Production Disaster" where 1,000 units arrive with the wrong texture, and you have zero recourse because you approved the digital proof.

Strategic Mitigation: The "Pre-Production Sample" (PPS)

To balance risk and speed, I recommend a strict protocol for your lead time [blocked] planning:

- The "Golden Sample" Rule: Never approve mass production based on a "rough sample." Insist on a Pre-Production Sample (PPS) that is made with the actual mass production materials and machines.

- Parallel Processing: If the timeline is tight, approve the structure and material based on existing stock samples, and only run a custom sample for the logo application. This isolates the variable.

- Buffer for One Rejection: Always build your timeline assuming the first sample will be rejected. If you need the goods on November 1st, and production takes 30 days, do not start sampling on October 1st. Start on September 15th.

In quality control, optimism is a liability. Assuming your sample will be perfect on the first try is the surest way to miss your event deadline.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.