"I only need 50 units, and I need them by next Friday. Since it's a small order, surely you can just squeeze it in between the big ones?"

This is the most common misconception in production scheduling. To a client, a small order looks like a small gap in the schedule. To a scheduler, a small order is a Full Stop.

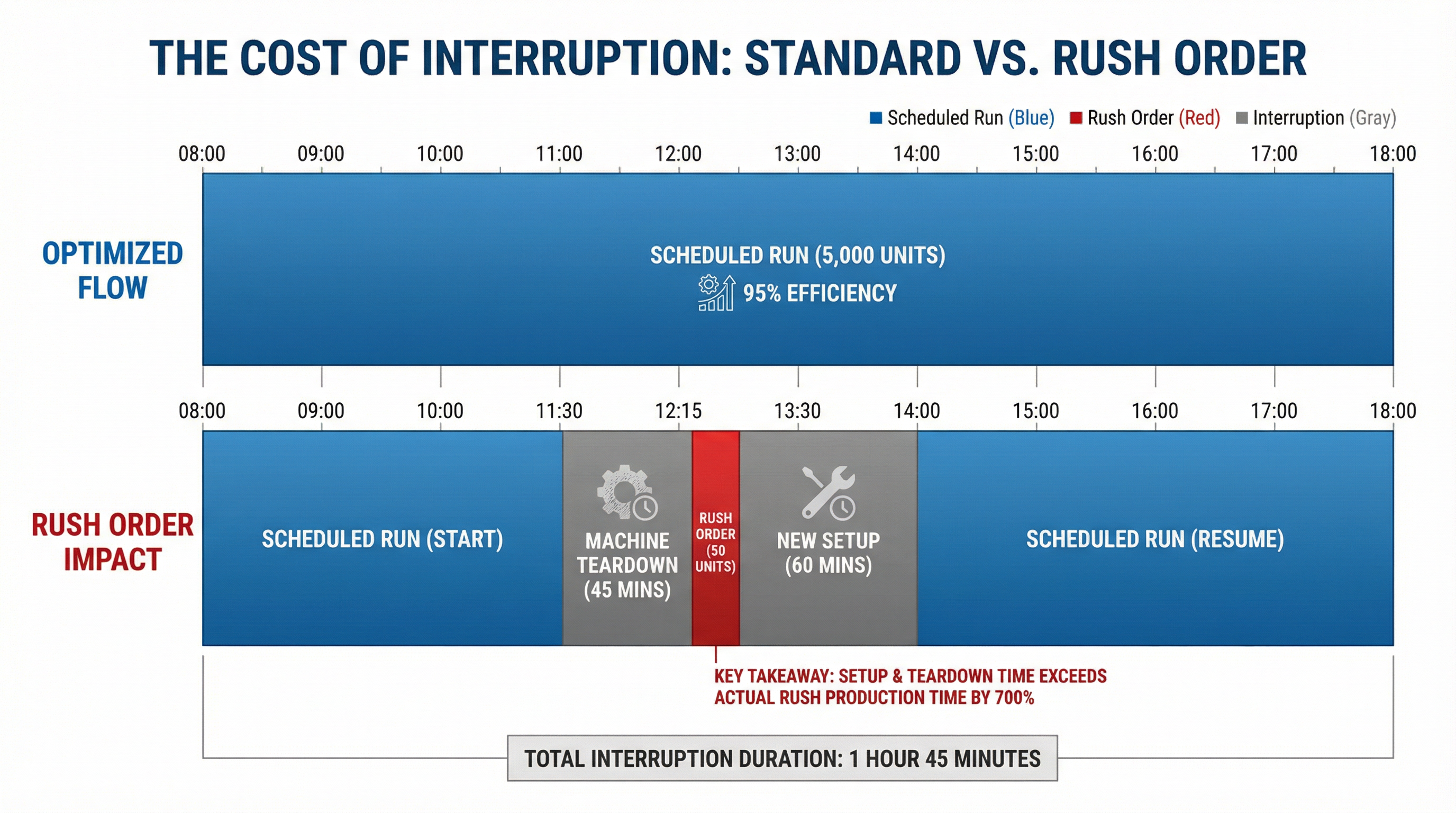

This article explains the "Opportunity Cost" of breaking a production run for a rush job, and why factories often reject small urgent orders even when they have "spare capacity."

[Image blocked: The Cost of Interruption: Standard vs. Rush Order]

The "Teardown" Trap: Why 10 Minutes Takes 4 Hours

Imagine our UV printer is running a 5,000-unit order for a major bank. It is calibrated, the jig is set, and it is printing 500 units per hour. The machine is in a "flow state."

To "squeeze in" your 50 units, we cannot just pause and resume. We must:

- Stop the 5,000-unit run (Efficiency drops to 0%).

- Teardown the current jig and clean the ink heads (45 mins).

- Setup your specific jig and calibrate your specific Pantone colors (60 mins).

- Run your 50 units (10 mins).

- Teardown your jig and wash the machine again (30 mins).

- Re-setup the bank's jig and re-calibrate (60 mins).

The Math: We spent 3 hours and 25 minutes of downtime to do 10 minutes of actual work for you. During that downtime, we could have printed 1,700 units for the bank.

The "Ripple Effect" on Other Orders

The impact doesn't stop at the machine. Inserting a rush order creates a chaotic ripple effect across the entire factory floor:

- Staging Chaos: Warehouse staff must stop picking the 5,000-unit order to find your 50 units, often buried in a different pallet.

- QC Bottleneck: Your 50 units need immediate Quality Control. This forces the QC manager to pull staff off the main line, leaving the 5,000-unit output piling up unchecked.

- Packing Disruption: The packing team has to switch from "Master Carton Mode" to "Individual Bubble Wrap Mode" for your small shipment, breaking their rhythm.

When you ask for a rush order, you aren't just asking for machine time; you are asking us to disrupt the workflow of 15 different people.

The "Overtime Myth"

Clients often say, "I'll pay for the overtime!" But overtime isn't a magic switch.

- Fatigue: Tired operators make mistakes. Running a complex setup at 9 PM for a small order increases the risk of misprints, which ruins the entire batch (since you have no spares).

- Supervisor Availability: If a problem happens during overtime, the senior engineers have gone home. Who fixes the machine if it jams?

Why We Say "No" (Or Charge Double)

If we accept your 50-unit rush order at a standard price, we lose money. The "Rush Fee" or "High MOQ" isn't a penalty; it is compensation for the 1,700 units of lost capacity on the main line and the operational chaos it causes.

How to Get Your Rush Order Accepted

If you are desperate, don't ask for a favor. Offer a solution that respects the scheduler's constraints:

-

"Piggyback" on an Existing Run: Ask: "What are you running on the machine right now?" If they are running Black Notebooks, and you are okay with Black Notebooks, we don't need to change the jig or ink. We can just slide your 50 units onto the end of the belt.

-

Accept "Digital" over "Offset": Digital printing (UV/DTG) has near-zero setup time. If you accept a digital print instead of a hot stamp or silkscreen, we can genuinely "squeeze you in" during a lunch break without disrupting the main line.

-

Offer "Open Delivery": Instead of "Must have by Friday," say "Ready whenever you have a gap." This allows the scheduler to slot you in during a natural changeover, avoiding the forced teardown cost.

Summary

In manufacturing, Time = Volume. A small order takes just as much setup time as a large one. If you want speed and low volume, you must be flexible on the product specs to match what is already on the line.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.