The transformation of a discarded mineral water bottle into a high-performance corporate polo shirt is a triumph of modern polymer engineering. As a Textile Manufacturing Engineer, I oversee the production of Recycled Polyethylene Terephthalate (rPET) fabrics. This process is not just about melting plastic; it is about purifying and restructuring polymer chains to match the quality of virgin polyester.

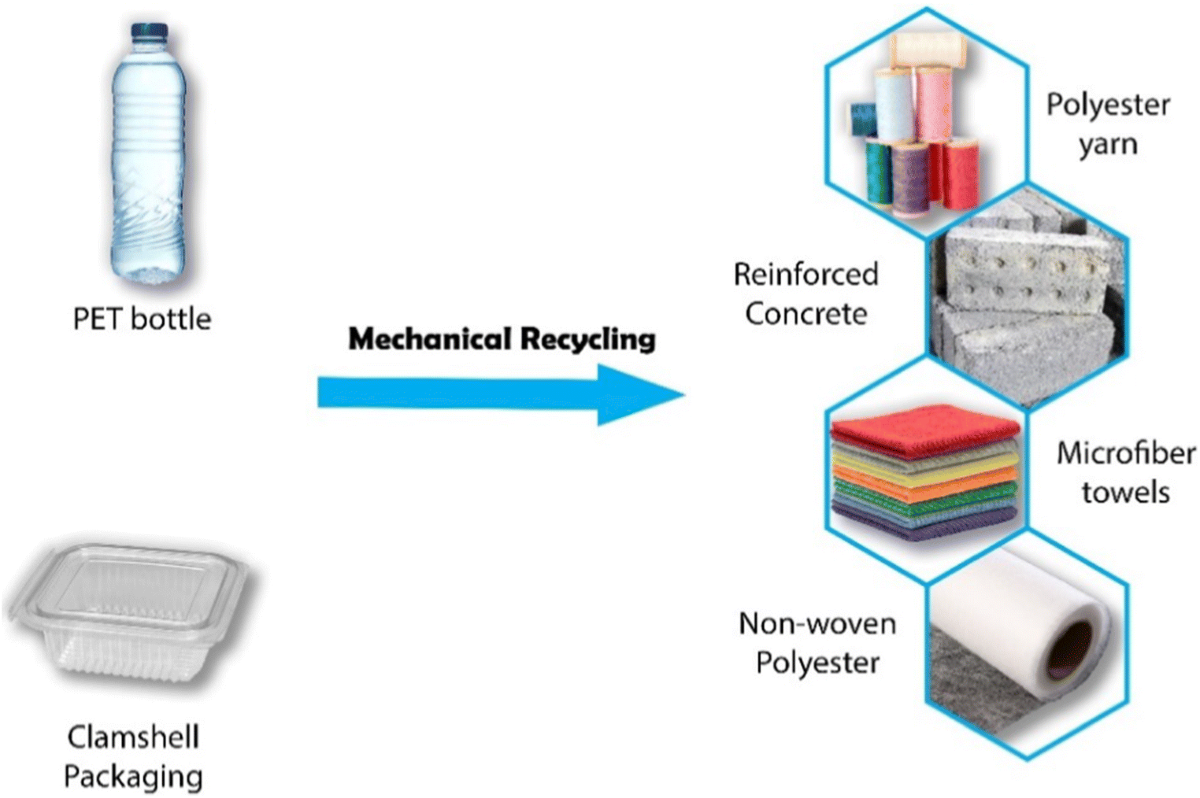

The Mechanical Recycling Process

It starts at the recovery facility. Bales of PET bottles are sorted, and caps/labels (made of PP/PE) are removed. The bottles are washed and shredded into 'flakes'. These flakes are the raw currency of the industry. The critical step is the 'super-cleaning' process, where the flakes are heated and vacuum-treated to remove volatile contaminants. They are then extruded into pellets. These pellets are melted at 280°C and forced through a spinneret—a shower-head like device with microscopic holes—to create continuous filaments. These filaments are drawn (stretched) to align the molecules, giving the fiber its strength.

Texture and Performance Engineering

Early rPET fabrics felt rough and plastic-like. Today, we use advanced texturizing techniques. By crimping the fibers and blending them with cotton or spandex, we create 'spun-poly' fabrics that mimic the soft hand-feel of natural cotton while retaining the moisture-wicking and durability properties of polyester. For corporate jackets, we use high-denier rPET for abrasion resistance. For t-shirts, we use micro-denier fibers for softness against the skin.

The Carbon Footprint Advantage

Manufacturing rPET generates 79% less carbon emissions than producing virgin polyester from crude oil. It also saves energy and diverts waste from landfills. However, dyeing rPET can be challenging due to impurities in the recycled base. We use specialized disperse dyes and high-pressure dyeing vessels to ensure deep, consistent color fastness (Grade 4-5) that meets corporate branding standards. The result is a garment that tells a powerful story of regeneration, allowing companies to wear their values on their sleeves.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.