In the domain of corporate stationery manufacturing, the decision between Polyurethane (PU) leather and genuine leather is rarely just about cost. It is a technical decision that impacts the product's longevity, tactile performance, and brand perception. As a material engineer who has spent over a decade testing substrate durability for the Southeast Asian market, I have observed that the "real vs. fake" debate is outdated. The 2025 procurement environment requires a nuanced understanding of polymer science versus organic histology. This report dissects the structural and functional differences between these two materials, specifically for the application of high-end corporate notebooks and planners.

Microstructure and Haptics: The Fibrous vs. The Cellular

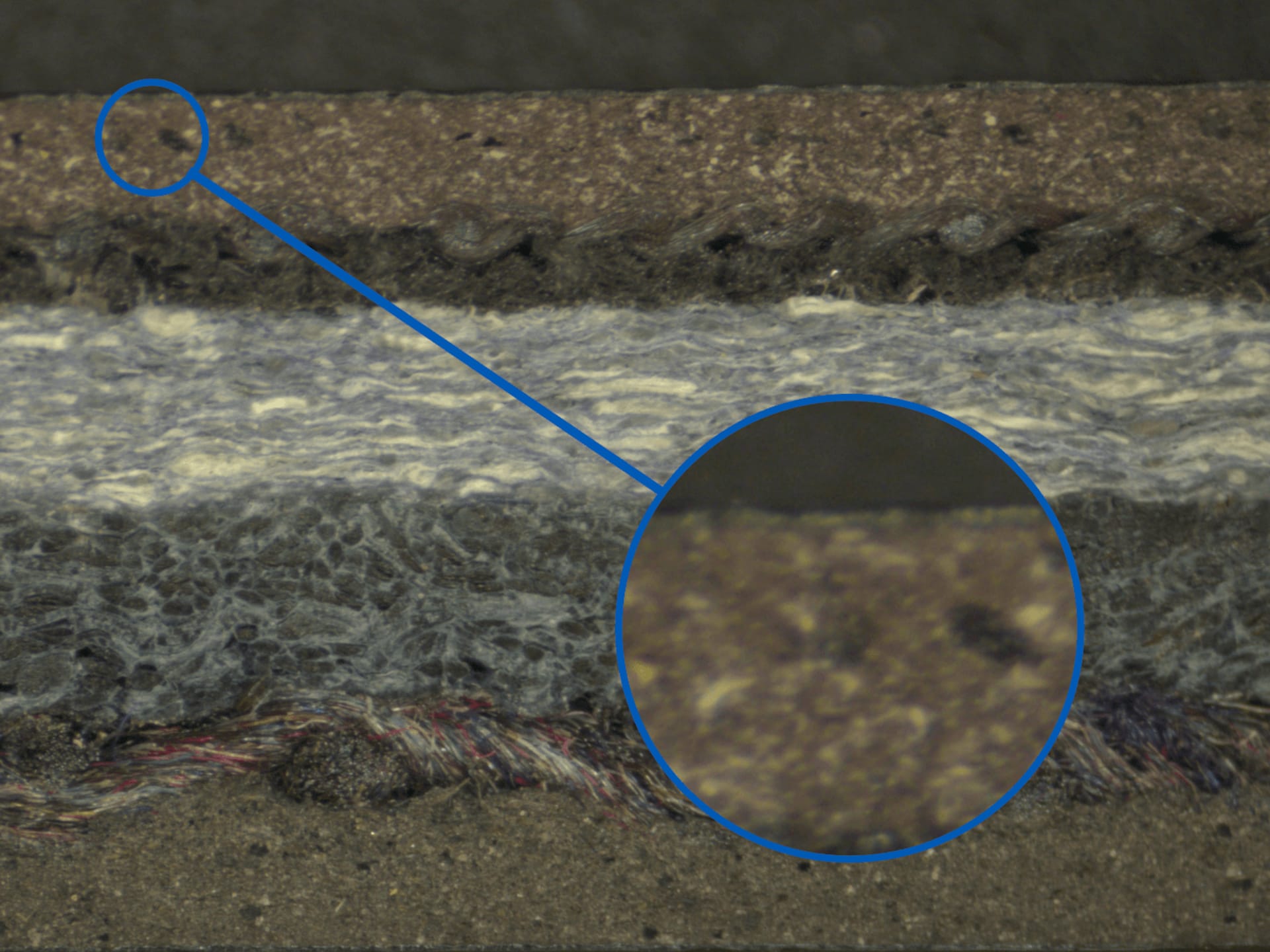

To understand why these materials behave differently under stress, we must look at them under a microscope. Genuine leather, specifically the top-grain cowhide often used in premium gifts, consists of a dense, random weave of collagen fibers. This organic structure provides exceptional tensile strength and breathability. When you bend a genuine leather cover, the fibers slide past each other, creating a smooth, rolling curve. It develops a patina over time because the porous surface absorbs oils and moisture, altering its chemical composition slightly without degrading its structural integrity.

In contrast, PU leather is a composite material. It typically consists of a base layer (often split leather, polyester, or cotton) coated with a flexible polyurethane polymer. Under magnification, PU reveals a uniform, cellular structure. It does not have fibers. This uniformity is both its strength and its weakness. It allows for perfect color consistency across 10,000 units—a feat impossible with genuine leather, where every hide varies. However, it lacks the self-healing properties of collagen. When scratched, the polymer layer is permanently severed.

The "Smell Test" Fallacy One of the most persistent myths in procurement is that you can identify genuine leather solely by smell. In 2025, this is dangerously inaccurate. High-end PU manufacturers now infuse synthetic leathers with fragrance oils that mimic the tannins found in vegetable-tanned leather. Conversely, heavily processed genuine leather (coated with thick pigments) may smell more like acrylic paint than hide. A more reliable field test is the "water drop" method. Genuine leather (unless heavily sealed) will darken as it absorbs a drop of water within seconds. PU leather, being hydrophobic, will repel the water, which will sit on the surface as a bead.

Thermal Embossing: The Thermodynamics of Branding

For corporate clients, the ability to brand the cover is paramount. The most common method is blind embossing (debossing), where a heated metal die is pressed into the material. The reaction of the two materials to heat is fundamentally different.

Genuine Leather: Compression and Darkening When you apply heat (approx. 120°C - 150°C) and pressure to genuine leather, you are essentially compressing the collagen fibers and slightly burning the tannins. This results in a permanent, darkened impression that feels organic. The depth of the emboss is limited by the density of the hide; press too hard, and you risk cutting the fibers.

Thermo-PU: The Color-Change Reaction Standard PU does not change color when heated; it just melts or flattens. However, "Thermo-PU" (or thermal-reactive PU) is engineered specifically for this industry. It contains a heat-sensitive layer beneath the surface skin. When the heated die (approx. 160°C - 180°C) strikes the material, the top layer becomes transparent or thins out, revealing the darker layer underneath. This creates a high-contrast, sharp logo that looks almost like it was printed, but with the depth of an emboss.

- Production Note: If your supplier uses standard PU instead of Thermo-PU, your logo will be invisible. Always specify "Thermo-PU" in your BOM (Bill of Materials).

Hydrolysis Resistance: The Tropical Killer

For the Malaysian market, the biggest enemy of PU leather is humidity. This brings us to the phenomenon of Hydrolysis. This is a chemical breakdown where the polyurethane polymer reacts with water molecules in the air, causing the coating to flake off and leave a sticky mess. We have all seen those cheap faux leather chairs peeling after a year.

In a tropical climate like Kuala Lumpur, where relative humidity often exceeds 80%, standard PU has a lifespan of maybe 12-18 months. For a 2025 corporate diary, this is unacceptable.

- The Solution: You must specify "Hydrolysis-Resistant PU" (often rated as 3-year, 5-year, or 10-year hydrolysis resistance). These materials are formulated with polycarbonate diols instead of standard polyether or polyester polyols, making them significantly more stable against moisture.

- Genuine Leather: Being organic, genuine leather is immune to hydrolysis. However, it is susceptible to mold growth if stored in damp, dark conditions without airflow. It requires maintenance (conditioning) to prevent drying out and cracking, whereas high-grade PU is maintenance-free until the chemical bond eventually fails.

Cost-Benefit Analysis for Mass Production

When ordering 5,000 notebooks, the price delta is massive.

- Genuine Leather: High cost ($15-$30+ per unit depending on grade). High waste factor (irregular hides mean 20-30% offcuts). High variation (clients must accept natural markings/scars).

- PU Leather: Moderate cost ($3-$8 per unit). Low waste (comes in rolls). Zero variation.

The "Batch Color" Trap While PU offers consistency, a common production failure occurs when a factory switches PU batches mid-order. Even with a Pantone reference, different production runs of PU can have slight metamerism issues (looking different under different light sources).

- Mitigation: For orders over 2,000 units, insist that the factory buys the PU material from a single dye lot. Request a "master sample" from that specific lot before mass production begins.

Environmental Impact: The 2025 Shift

Sustainability is the new baseline. Genuine leather is a byproduct of the meat industry, making it technically renewable, but the tanning process (especially chrome tanning) is chemically intensive. Vegetable-tanned leather is the eco-friendly alternative but is stiffer and more expensive. On the PU side, 2025 sees the rise of "Bio-PU" or "Vegan Leather" made from plant-based polymers (cactus, apple, pineapple fibers) mixed with PU. These reduce reliance on fossil fuels. However, verify the percentage of bio-content. Many "bamboo leathers" are just 10% bamboo powder mixed into 90% standard plastic.

"My boss insists on genuine leather for the VIP gifts, but our budget is tight. Is there a middle ground?" Expert Response: Yes, consider "Recycled Leather" (or Bonded Leather). It is made by shredding leather scraps and bonding them with polyurethane. It smells like leather, feels like leather, and embosses like leather, but costs about 40% less and cuts with the efficiency of PU.

Summary of Technical Specifications

| Feature | Genuine Leather (Top Grain) | Thermo-PU (High Grade) |

|---|---|---|

| Primary Component | Collagen Fibers (Cowhide) | Polyurethane + Fabric Backing |

| Water Resistance | Low (Absorbs water) | High (Hydrophobic) |

| Humidity Resistance | High (Risk of Mold) | Variable (Risk of Hydrolysis) |

| Embossing Temp | 120°C - 150°C | 160°C - 180°C |

| Visual Aging | Develops Patina | Remains Static / Peels |

| Unit Cost Index | 100 (Baseline) | 20 - 30 |

By understanding these material properties, you can move beyond the binary of "real vs. fake" and choose the substrate that aligns with your project's budget, climate conditions, and brand ethos.

Advanced Durability Testing Protocols

In our lab, we subject both materials to rigorous stress tests to simulate 3 years of corporate usage.

- The Bally Flex Test: A machine flexes the material 50,000 times. Genuine leather usually passes with zero cracks. Standard PU often cracks at 15,000 cycles. High-grade Hydrolysis-Resistant PU can survive 100,000 cycles.

- The Jungle Test: Samples are placed in a chamber at 70°C and 95% humidity for weeks. This accimproves the hydrolysis process. If a PU sample survives 3 weeks in the "Jungle," it is rated for 3 years of tropical use.

- The Taber Abrasion Test: A spinning abrasive wheel grinds the surface. Genuine leather wears down gracefully. PU leather eventually loses its top skin, revealing the fabric base underneath—a catastrophic aesthetic failure.

Conclusion: Making the Right Choice

For a CEO's personal journal or a gift to a Minister, genuine leather remains the gold standard due to its prestige and longevity. However, for a mass-distributed staff diary or a conference notebook (500+ units), high-grade Thermo-PU is the superior engineering choice. It offers better branding visibility, lower cost, and sufficient durability—provided you specify the correct hydrolysis resistance rating.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.