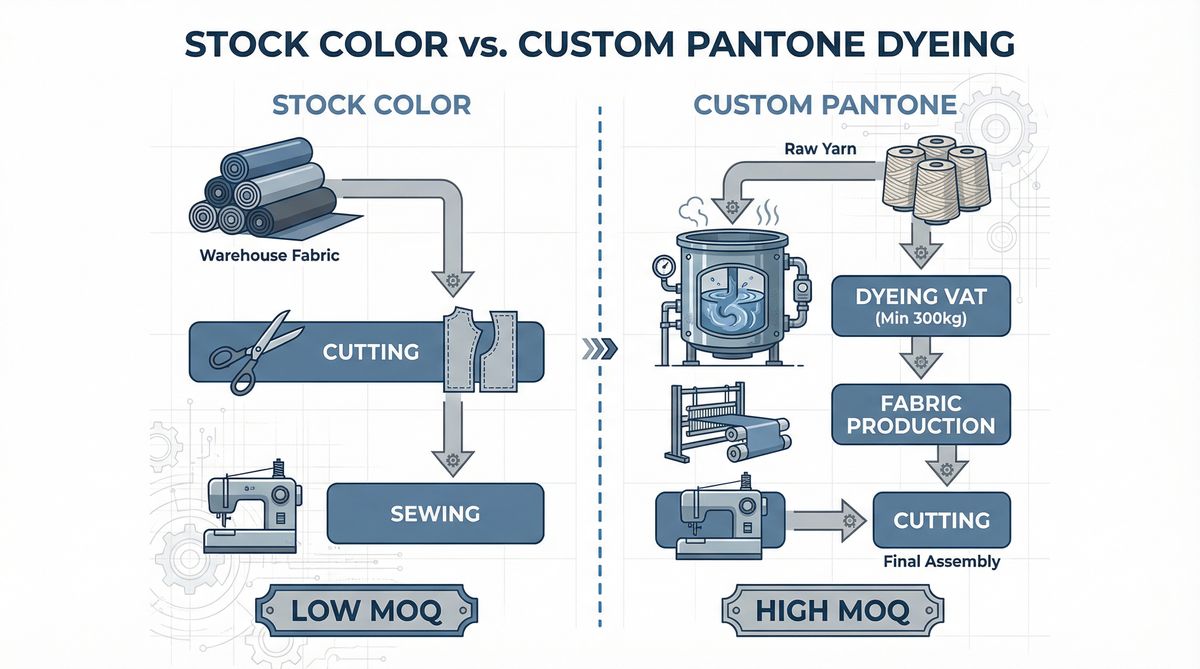

A frequent standoff in corporate gifting occurs between Brand Managers (who demand exact Pantone adherence) and Procurement Managers (who need to keep inventory low). The conflict usually centers on a simple question: "Why can I buy 50 blue notebooks, but I need to buy 500 if I want them in Pantone 286C?"

The answer lies in the fundamental difference between Stock Procurement and Custom Manufacturing.

[Image blocked: Stock Color vs. Custom Pantone Dyeing Process]

The "Stock Fabric" Constraint

For standard items (notebooks, bags, umbrellas), factories buy raw material (PU leather, nylon, canvas) in massive rolls from material mills. They stick to "safe" colors that sell in high volume: Black, Navy Blue, Red, and Grey.

- Low MOQ (50 units): When you order a "Blue Notebook," the factory is simply cutting from a roll of blue leather they already have sitting on a shelf. The only setup is for your logo printing.

- High MOQ (500+ units): When you request "Pantone 286C," the factory likely does not have that specific shade in stock. They must go upstream to the material mill and order a custom dye lot.

The Upstream "Dye Lot" Minimum

Material mills operate giant dyeing vats. They cannot dye just 10 meters of fabric; they must dye a minimum batch (e.g., 500 meters) to ensure color consistency and machine efficiency.

This 500-meter minimum from the mill translates directly into a 500-unit minimum for the finished product. If the factory orders the material for you, they must use it all up—they cannot risk holding leftover "Pantone 286C" fabric that no other client wants.

The "Approximation" Compromise

If your volume cannot support the custom dyeing MOQ, the standard industry solution is "Closest Stock Match."

We take your Pantone chip and physically compare it against the 20–30 stock colors available in the market. Often, we can find a stock color that is a 90–95% visual match. For most corporate applications, this slight deviation is an acceptable trade-off to reduce the MOQ from 500 units down to 50 units.

Summary for Brand Teams

Strict Pantone matching triggers a Custom Manufacturing workflow, which inherently carries a higher MOQ due to raw material dyeing constraints. If the order volume is under 500 units, flexibility in color acceptance is the single most effective way to lower costs and lead times.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.