One of the most frustrating moments in product development occurs when a client approves a 50-unit order for premium metal pens, only to have the entire project stall because they also requested a "custom-sized box with our logo printed all over it."

From a factory engineering perspective, the product and the packaging are two completely separate manufacturing streams. While we can laser engrave 50 pens in an hour, manufacturing 50 custom-sized rigid boxes is technically impossible without incurring exorbitant costs.

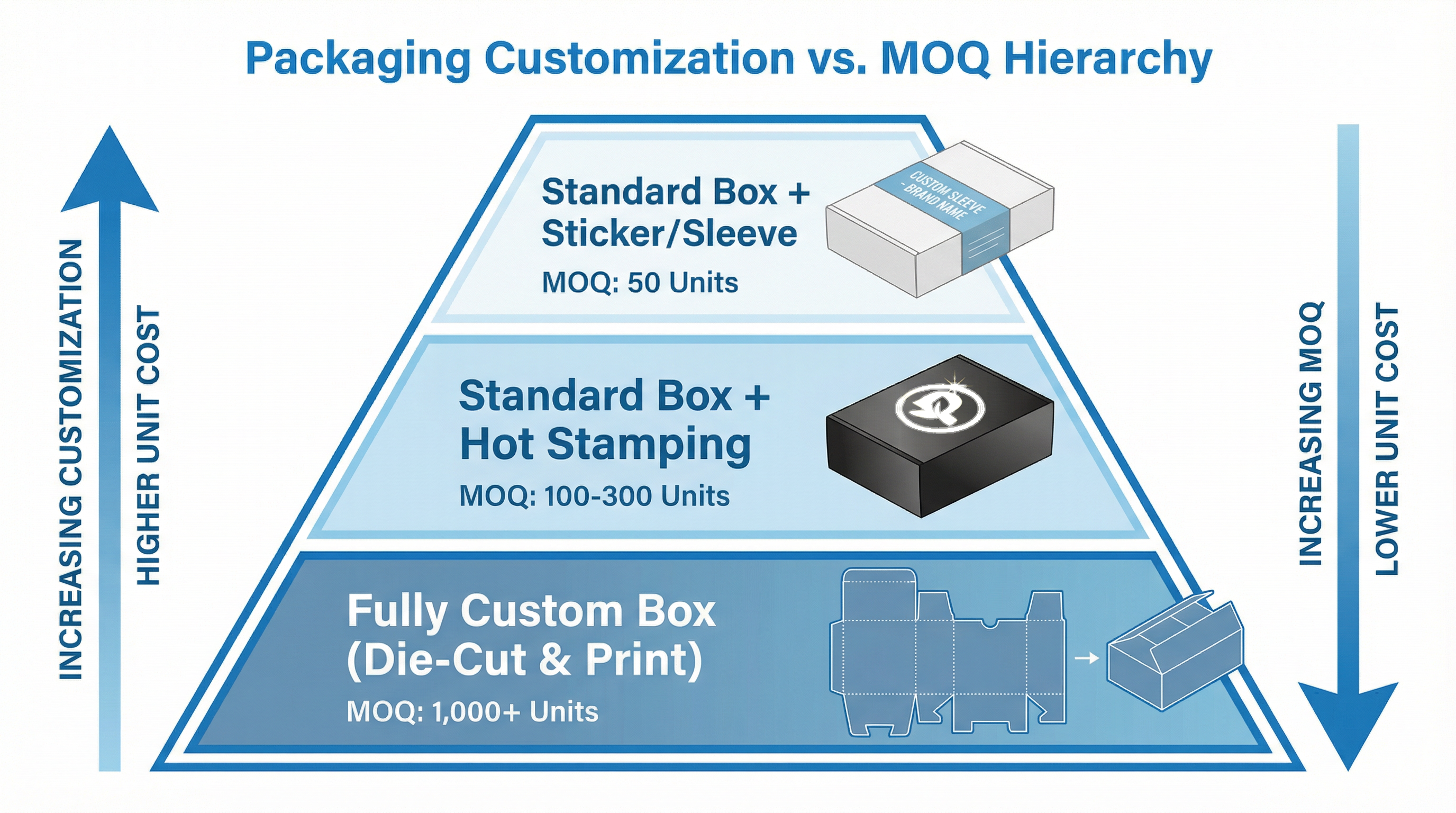

This article breaks down the Die-Cut Tooling constraint that dictates packaging MOQs.

[Image blocked: Packaging Customization vs. MOQ Hierarchy]

The "Knife Mold" (Die-Cut) Reality

To make a box, we don't just fold paper. We use a massive steel die (a "knife mold") to stamp out the specific shape from a cardboard sheet.

- The Fixed Cost: A custom knife mold costs between RM 400 and RM 800 depending on complexity.

- The Machine Setup: Setting up the die-cutting machine takes 1–2 hours of calibration.

- The Material Waste: The first 20–30 sheets are often wasted just to align the print with the cut.

If you order 50 boxes, the setup cost and waste alone might cost RM 1,000. Divided by 50 units, that's a RM 20.00 surcharge per box—often more expensive than the gift inside. This is why factories set a hard MOQ of 1,000 units for fully custom-sized boxes; it's the break-even point where the setup cost drops to cents per unit.

The "Standard Tooling" Workaround

For orders under 500 units, the only viable engineering solution is to use Standard Tooling.

Factories maintain a library of "public molds"—pre-existing box sizes (e.g., A5 Notebook Box, Pen Box, Mug Box). By using an existing size, you eliminate the die-cut cost.

How to Customize Without a New Mold:

- Hot Stamping: We take a standard black box and hot-stamp your logo in Gold or Silver foil. This requires a small zinc plate (cheap) rather than a full steel die (expensive).

- Sleeve / Belly Band: We print a full-color paper sleeve that wraps around a standard white box. This gives the illusion of a fully custom box but is actually just a digital print run, which has a very low MOQ (50 units).

Summary for Project Managers

If your volume is under 1,000 units, never design the box size from scratch. Always ask the supplier for their "Standard Die-Cut List" first, and fit your design onto their existing structures. This simple engineering constraint check can save weeks of negotiation and thousands of Ringgit in tooling fees.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.