In the high-stakes world of corporate branding, the fidelity of your logo on a notebook or letterhead is not just a detail—it is a statement of precision. As a production manager who has overseen the printing of millions of corporate impressions, I often guide clients through the critical decision: Offset Lithography or Digital Printing? The choice is rarely about 'better' or 'worse'; it is an engineering trade-off between volume, fidelity, and substrate interaction.

The Mechanics of Lithography: When Volume Dictates Quality

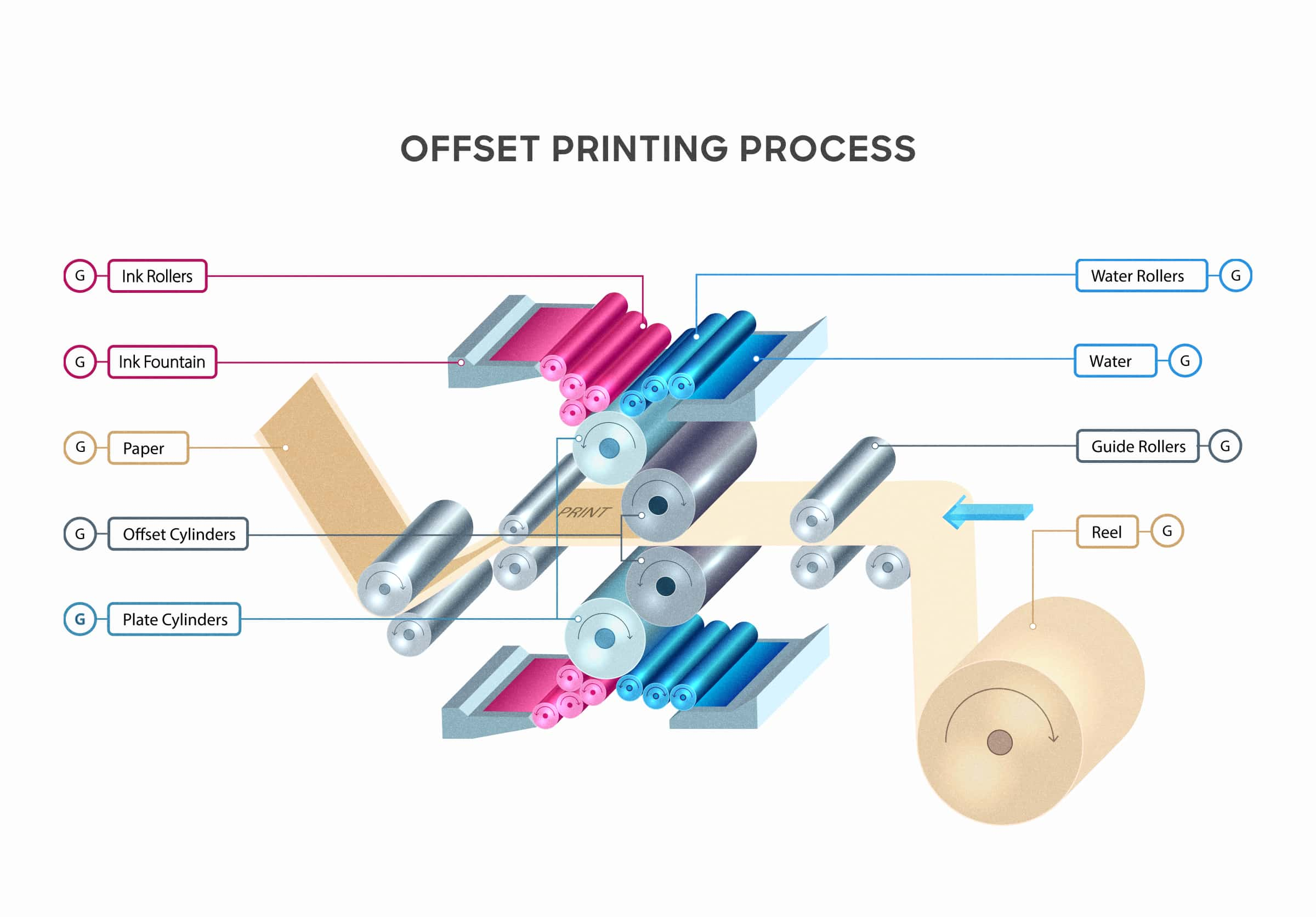

Offset printing is the granddaddy of high-volume production. It operates on the principle that oil and water do not mix. An aluminum plate is etched with the image; the non-image areas attract a water-based dampening solution, while the image areas attract the oil-based ink. This image is then 'offset' onto a rubber blanket cylinder, which finally transfers it to the paper. This indirect transfer is crucial—it allows for a softer, more consistent ink laydown on textured stocks like linen or laid paper, which are favorites for executive stationery.

For a run of 5,000 corporate diaries, offset is the only logical choice. Once the plates are made—a fixed setup cost—the unit cost drops precipitously. Moreover, offset allows for the use of Pantone Matching System (PMS) spot colors. If your brand's corporate blue is Pantone 286C, offset printing mixes that exact ink formula. Digital printing, by contrast, simulates it using CMYK toner, which can result in slight metamerism—where the color looks different under fluorescent office lights versus natural daylight.

Digital Printing: The Agility of Variable Data

Digital printing, utilizing electrostatic toner or inkjet technology, bypasses the plate-making process entirely. The digital file goes straight to the press. This makes it the undisputed king of short runs and tight deadlines. If you need 50 presentation folders for a board meeting tomorrow, digital is your savior. The setup time is near zero.

However, the real power of digital lies in Variable Data Printing (VDP). Imagine printing 500 notebooks, each personalized with a different employee's name on the cover. Offset cannot do this without stopping the press to change plates for every single unit—an impossible feat. Digital presses handle this data stream effortlessly, changing the image for every revolution of the drum.

Substrate Interaction and Tactile Feel

From a tactile perspective, offset ink penetrates the paper fibers (uncoated stocks) or sits as a thin, smooth film (coated stocks). It feels integrated. Digital toner, on the other hand, sits on top of the paper surface and is fused by heat. On heavy coverage areas, this can create a slight relief or 'waxiness' that some designers find less premium. However, modern digital presses like the HP Indigo use liquid electro-ink that mimics the look and feel of offset ink, narrowing this gap significantly.

The Verdict for Malaysian Corporates

For our Malaysian clients, the decision often comes down to the annual procurement cycle. For the year-end bulk order of 10,000 calendars and diaries, we fire up the Heidelberg offset presses to ensure cost-efficiency and Pantone perfection. For the quarterly training manuals or urgent event flyers, the digital press runs 24/7. Understanding these production nuances ensures that your budget is optimized without compromising the integrity of your brand identity.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.