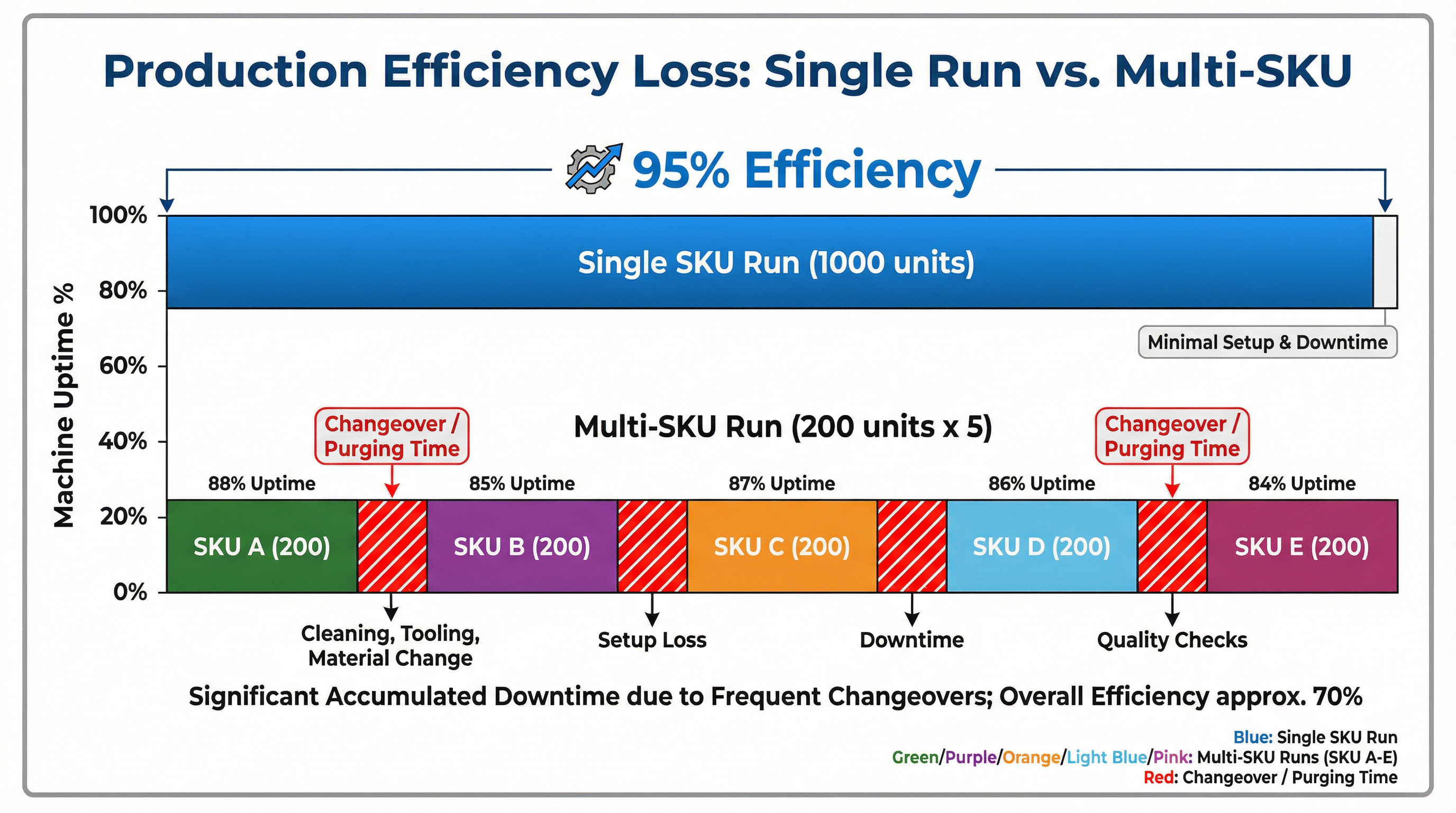

A common friction point in procurement negotiations is the "Total Volume Argument." A buyer will say, "I am ordering 1,000 units total—200 Red, 200 Blue, 200 Green, 200 Yellow, and 200 Black. Why are you charging me the high MOQ price for each color?"

From a factory floor perspective, you haven't ordered 1,000 units. You have ordered five separate runs of 200 units.

This article explains the hidden Changeover Costs that make multi-SKU orders significantly more expensive to produce than single-SKU runs.

[Image blocked: Production Efficiency Loss: Single Run vs. Multi-SKU]

The "Changeover" Reality

In manufacturing, efficiency comes from continuous momentum. When a machine is running, it prints money. When it stops, it burns money.

Every time we switch from "Red Ink" to "Blue Ink" on a silkscreen line or injection molding machine, the following must happen:

- Stop the Machine: Production halts completely.

- Purge the System: The old ink/plastic must be flushed out. This creates waste material (scrap).

- Clean the Tooling: Screens must be washed; nozzles must be scrubbed.

- Recalibrate: The new color is loaded, and test units are run to ensure color accuracy.

This process takes 30–60 minutes per switch. If you split 1,000 units into 5 colors, we lose 4 hours of production time just cleaning machines. That is 4 hours where we could have produced another 2,000 units.

The "Downtime Ratio"

- Single Run (1,000 Blue): 1 hour setup + 4 hours running = 80% Efficiency

- Multi-Run (200 x 5 Colors): 5 hours setup + 4 hours running = 44% Efficiency

Because the machine is idle for more than half the shift, the factory must charge you a higher unit price (or a "Changeover Fee") to recover the cost of that lost time.

How to Engineer Around This

If your marketing team insists on multiple colors but your budget is tight, consider these strategies:

-

Standardize the Hard Goods, Customize the Soft Goods: Order 1,000 Black notebooks (Single SKU = Low Price). Then, use a Belly Band or Sticker to differentiate them (e.g., Red band for HR, Blue band for Sales). Paper printing has much lower changeover costs than hard goods manufacturing.

-

The "80/20" Split: Instead of an even split (200x5), order 800 units in your primary corporate color (e.g., Navy Blue) to hit the efficiency tier, and 200 units in a secondary color (e.g., White) for VIPs. You might pay a surcharge on the 200, but the bulk of your order gets the best price.

Summary for Procurement

When negotiating, remember: MOQ applies per SKU, not per Purchase Order. If you fragment your volume, you fragment your bargaining power. Consolidating your color choices is the fastest way to slash unit costs without sacrificing quality.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.