In strategic sourcing, we are trained to negotiate the "Ex-Factory Date" (the day goods leave the factory). We assume that once the goods are on the truck or ship, the timeline is purely a function of distance.

This is a dangerous oversimplification. In cross-border procurement—especially for corporate gifts coming into Malaysia from China or Vietnam—the "Last Mile" is not a distance; it is a regulatory gauntlet.

The "Friday Arrival Trap"

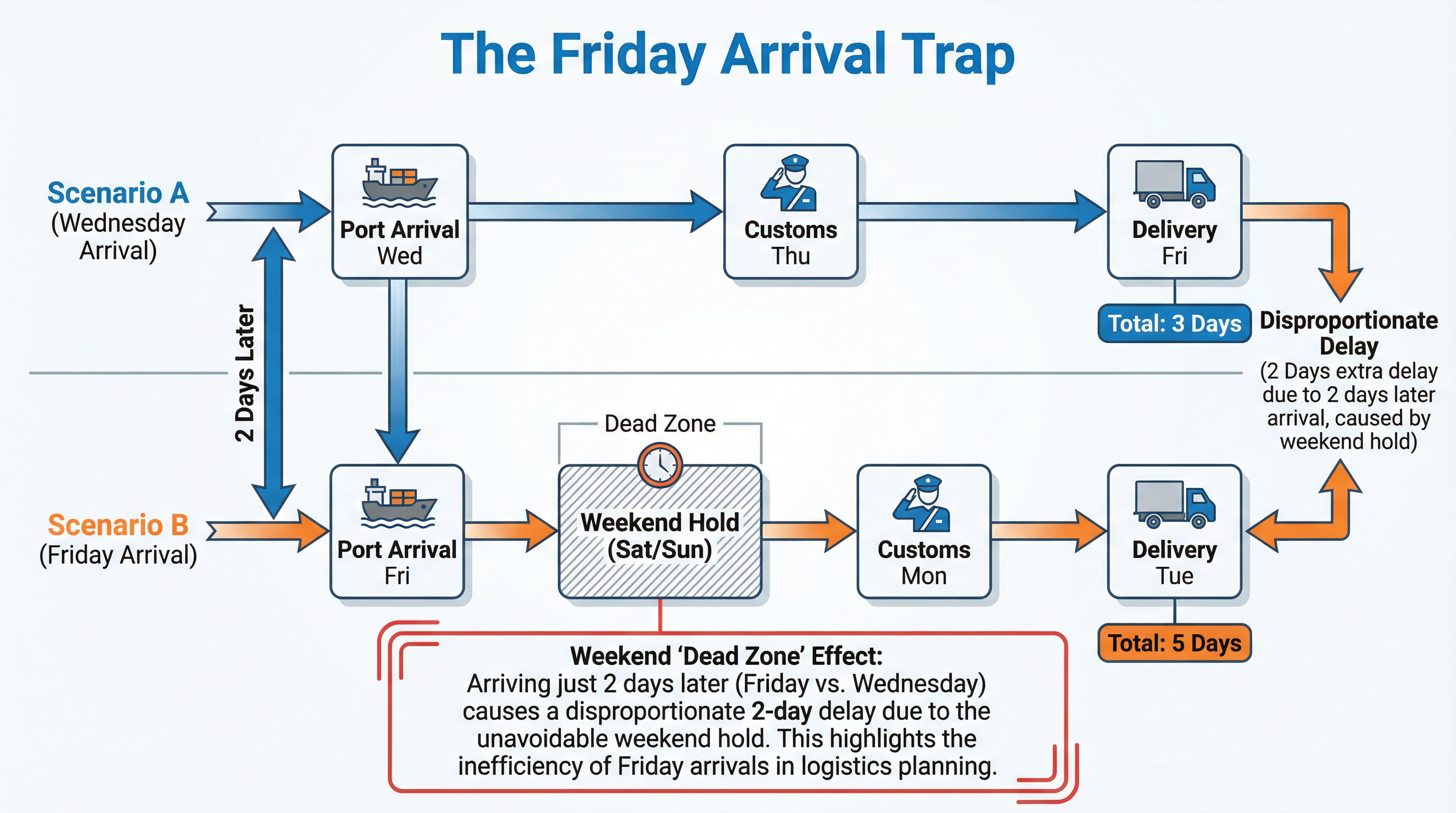

The most common invisible delay occurs when a shipment is scheduled to arrive at Port Klang or KLIA on a Friday afternoon.

Logistically, the vessel has arrived. But administratively, the weekend "Dead Zone" has begun.

- Customs Officers: Operate on skeleton crews or are off-duty.

- Forwarding Agents: Often close their documentation counters by 5:00 PM.

- Banks: Cannot process duty payments until Monday morning.

If your goods dock at 4:00 PM on Friday, they will sit in the bonded warehouse until Monday morning. Clearance starts Monday, delivery happens Tuesday.

The Math: A 2-day difference in arrival (Wednesday vs. Friday) results in a 4-day difference in delivery.

[Image blocked: Diagram comparing a Wednesday Arrival (3 days to delivery) vs. a Friday Arrival (5 days to delivery), visualizing the 'Weekend Dead Zone' effect.]

The "Customs Inspection" Variable

Another blind spot is the "Red Lane" probability. Most shipments go through the "Green Lane" (automatic clearance). But if your HS Code is ambiguous—common with "Gift Sets" containing mixed items like a power bank (battery regulation) and a notebook (paper tax)—customs may flag it for manual inspection.

A manual inspection adds 48–72 hours to the timeline. If you calculated your lead time [blocked] with zero buffer for customs, this inspection will cause you to miss your event.

How to "De-Risk" the Last Mile

- Target a Tuesday/Wednesday Arrival: When booking freight, ask your forwarder for the ETA. If it's Friday, push for an earlier vessel or accept that you won't see the goods until Tuesday.

- Pre-Clearance Documentation: Ensure your supplier sends the Commercial Invoice and Packing List before the ship arrives. Your forwarder can submit the "Manifest" early, sometimes allowing for "Pre-Arrival Clearance."

- Separate "Risky" Items: Do not pack battery-operated items in the same carton as urgent paper products. If the batteries get held up, the entire shipment gets held up.

In procurement, the goods are not "arrived" when they hit the port. They are "arrived" when they clear the gate. Ignoring this distinction is why so many "on-time" shipments end up being late for the event.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.