As a Factory Project Manager, the most painful conversation I have with designers is telling them that their chosen paper color—the one that perfectly matches their brand guidelines—will delay their project by two months.

This is not because we are slow. It is because of how paper mills operate.

The Myth of "In Stock"

Most clients assume that a printing factory is like a stationery store: we have every color and texture of paper sitting on a shelf, ready to use.

In reality, we only stock Standard Papers (Simili 80gsm, Art Card 260gsm, etc.) in bulk.

Specialty Papers (textured, metallic, or specific Pantone-dyed papers) are not stocked. We order them from the paper mill only when you confirm your order.

The "Mill Run" Trap

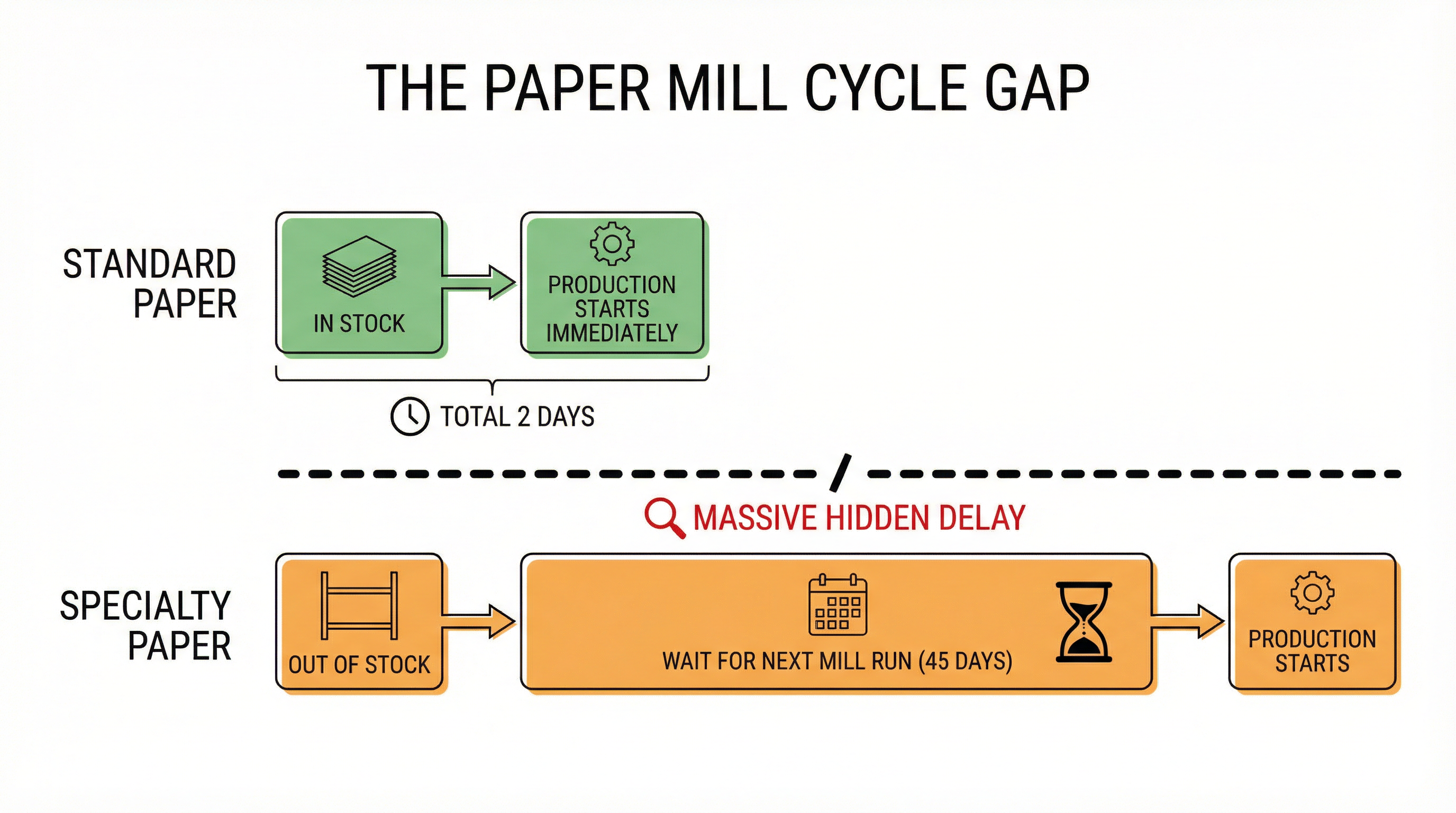

Paper mills do not produce every color every day. They operate on Production Cycles (Mill Runs).

- Week 1-2: They produce only White paper.

- Week 3: They produce only Cream paper.

- Week 4: They produce only Black paper.

If your design requires "Midnight Blue" textured paper, and the mill just finished their Blue run yesterday, they will not switch the machine back for your 500 notebooks. You have to wait for the next Blue run.

The Consequence: If you are lucky, the next run is next week. If you are unlucky, the next run is in 45 days.

[Image blocked: Technical timeline diagram comparing 'Standard Paper' (Immediate Start) vs. 'Specialty Paper' (45-Day Wait), visualizing the hidden delay of the Paper Mill Cycle.]

How to Avoid the Trap

- Ask for "Stock Availability" First: Before you fall in love with a specific paper sample, ask us: "Is this a stock item or a mill item?"

- Be Flexible with Shades: If "Midnight Blue" is a mill item with a long wait, ask if "Navy Blue" is available in stock. The difference is often invisible to the end-user but saves you 6 weeks of lead time [blocked].

- Book the Paper Early: If you must have that specific paper, pay a deposit to book the material before you finalize the artwork. This allows us to secure the stock while you are still tweaking the design.

The Takeaway: In manufacturing, material availability dictates the schedule. Don't let a specific shade of paper be the reason your event launch fails.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.