In the controlled environment of a corporate office, "weather" is just a traffic inconvenience. But on the factory floor in Malaysia, specifically during the monsoon transitions (April-May and October-November), weather becomes a dominant chemical variable.

As Quality Consultants, we often have to intervene when a project manager tries to "push" a factory to speed up production during a rainy week. They assume that machines run at a constant speed. They forget that the materials—paper, ink, and glue—are organic and highly sensitive to the Environmental Humidity Factor.

The Physics of the "Critical Delay Zone"

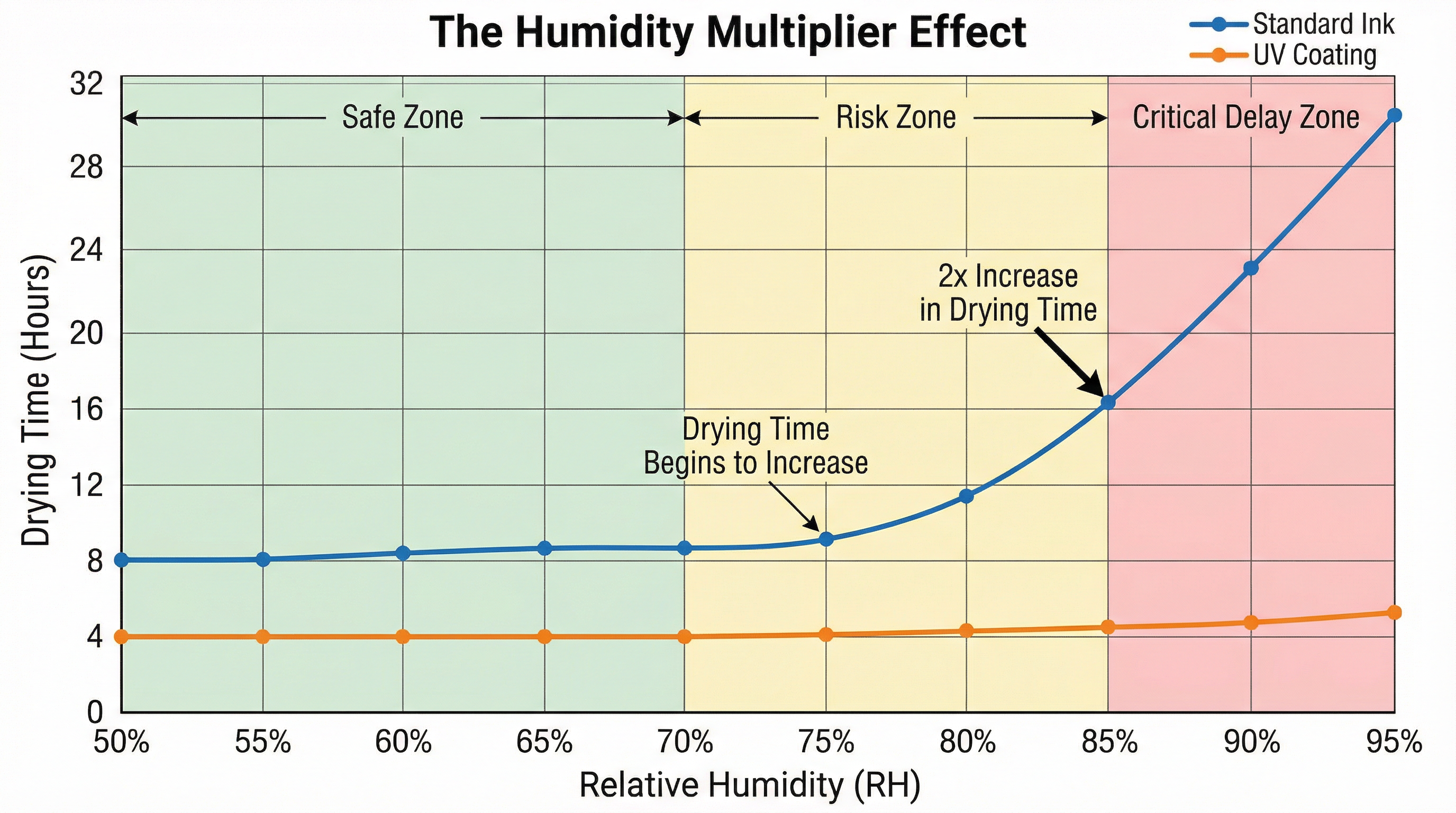

Most printing inks and binding glues rely on evaporation to cure. When the Relative Humidity (RH) in the production plant exceeds 85%—a common occurrence during Malaysian thunderstorms—the air is already saturated with moisture. It physically cannot absorb the solvents evaporating from the fresh print.

In practice, this is often where lead time [blocked] decisions start to be misjudged. A process that takes 4 hours at 60% RH does not just take "a little longer" at 90% RH; it can take 12 to 24 hours.

[Image blocked: Technical line graph showing the exponential increase in drying time as Relative Humidity exceeds 85%, marking the 'Critical Delay Zone' where standard production schedules fail.]

The Consequence of Rushing: Warping and Blocking

When a deadline is immovable, the temptation is to turn up the heat tunnels and force the drying process. This is a catastrophic error for two reasons:

- Paper Warping: Paper is hygroscopic; it absorbs moisture from the air. If you blast it with heat while it is damp, the fibers expand unevenly, causing the covers of your custom notebooks to bow or curl within days of delivery.

- Blocking (Sticking): If sheets are cut and stacked before the ink is 100% cured deep down (not just dry to the touch), the weight of the stack will cause the sheets to fuse together. This is known as "blocking," and it renders the entire batch unusable.

The "Buffer Day" Strategy

We advise all clients procuring paper products in Malaysia to build a "Monsoon Buffer" into their Q4 timelines. If your production window coincides with the rainy season, add 3 to 5 days specifically for "passive curing."

You cannot negotiate with physics. If the air is wet, the ink waits. Acknowledging this reality doesn't delay your project; it saves it from a 100% rejection rate.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.