When a client asks, "Can you just stamp our logo on the cover? It's a simple step," they are technically correct. The stamping action itself takes less than 3 seconds. However, from a production management perspective, this request introduces a catastrophic bottleneck known as the Velocity Gap.

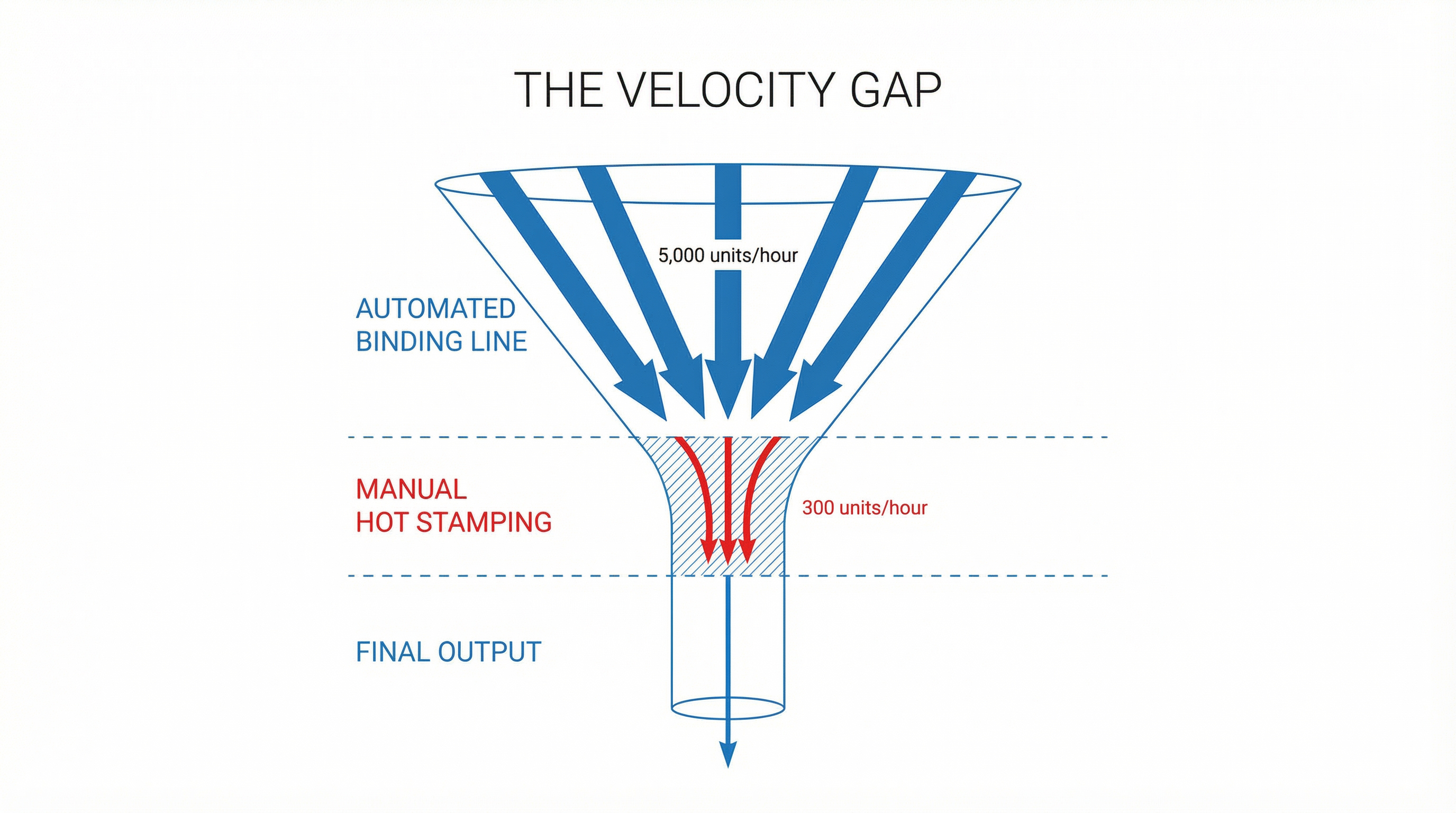

Modern notebook manufacturing is a tale of two speeds. The binding line—where pages are collated, glued, and covered—is a high-speed automated beast capable of churning out 5,000 units per hour. In contrast, custom finishing (Hot Stamping, Debossing, or Silk Screen) is a semi-manual "Pick-and-Place" operation.

The Math of the Bottleneck

A skilled operator on a hot stamping machine can process about 300 covers per hour. They must manually align each cover, trigger the press, check the quality, and stack it.

In practice, this is often where lead time [blocked] decisions start to be misjudged. If you order 10,000 notebooks:

- Binding Time: 2 hours (Automated)

- Stamping Time: 33 hours (Manual)

Your "simple logo" has just shifted the production constraint from a machine that finishes in a morning to a process that takes 4 full shifts (or 2 days of double shifts).

[Image blocked: Technical funnel diagram illustrating the 'Velocity Gap', showing how a wide, fast automated flow (5,000 units/hr) gets choked by a narrow, slow manual finishing process (300 units/hr).]

The "Queue Effect"

The problem is compounded when multiple orders hit the finishing department simultaneously. While the binding line clears orders quickly, the stamping department accumulates a backlog. An order that took 2 hours to bind might sit in the "Stamping Queue" for 5 days simply waiting for a machine to free up.

Mitigating the Impact

To navigate this bottleneck without sacrificing customization:

- Pre-Stamp Covers: If you have a recurring annual order, authorize us to stamp the covers before binding during the off-peak season. We store the stamped covers and bind them on demand.

- Laser Engraving: For metal pens or specific PU leathers, laser engraving is significantly faster (1,000+ units/hr) and automated, bridging the velocity gap.

- Standardize Positions: Custom positions (e.g., "bottom right corner, 15mm from edge") require slower manual alignment. Standard positions (e.g., "optical center") allow for faster jig setup and processing.

Understanding the Velocity Gap allows you to plan realistic timelines. It's not that we can't stamp faster; it's that manual craftsmanship simply cannot keep pace with industrial automation.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.