In high-pressure procurement, the most common request I hear is: "Can you skip the waiting period and ship immediately after production?"

The answer is always no. Not because we are stubborn, but because of chemistry.

When we manufacture custom notebooks, we use industrial adhesives (glue) for binding and solvent-based inks for logo printing. These substances contain moisture and volatile organic compounds (VOCs) that need to evaporate. This process is called Curing.

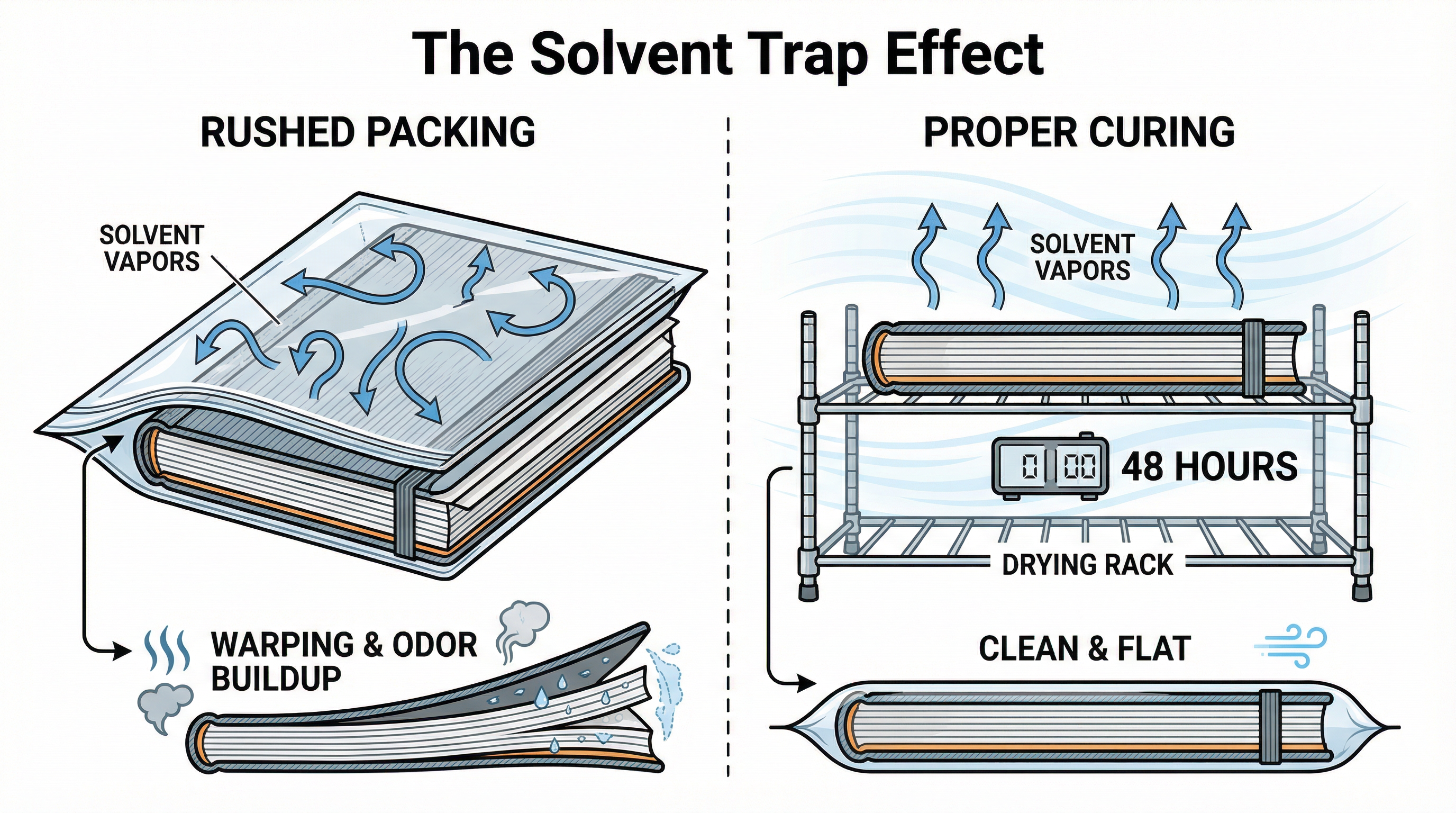

The "Solvent Trap" Phenomenon

If we succumb to pressure and pack the notebooks into individual polybags immediately after they come off the line (while they are still "warm"), we create a sealed environment.

The moisture and solvents that are trying to evaporate get trapped inside the plastic bag.

- Odor Buildup: When your CEO opens the box at the event, they will be hit with a strong, chemical smell of glue and ink.

- Warping: The trapped moisture re-absorbs into the paper cover, causing it to curl or "warp" within 24 hours.

- Mold Risk: In Malaysia's humid climate, trapped moisture inside a warm polybag is a perfect breeding ground for mold.

The Math: Saving 2 days on lead time [blocked] = 100% Risk of Product Rejection.

[Image blocked: Technical diagram comparing 'Rushed Packing' (Solvent Trap) vs. 'Proper Curing' (48 Hours), showing how trapped vapors cause warping and odor.]

The 48-Hour Rule

We enforce a strict 48-Hour Curing Buffer for all bound stationery products.

- Hours 0-24: Products sit on open drying racks in a humidity-controlled room.

- Hours 24-48: Products are stacked under weights to ensure the covers dry flat and the glue sets permanently.

Only after this 48-hour period do we allow the products to be inserted into polybags or gift boxes.

How to Factor This Into Your Timeline

When you see a production timeline of "14 Days," ask your supplier: "Does this include the curing time?"

Often, the "14 Days" refers to the mechanical production time. The curing time is an invisible 2-3 days that gets tacked on at the end. If you are planning a launch event, you must account for this.

The Bottom Line: A notebook that smells like glue is not a premium gift; it is a liability. The 48 hours we spend curing the product is the difference between a successful branding exercise and an embarrassing PR disaster.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.