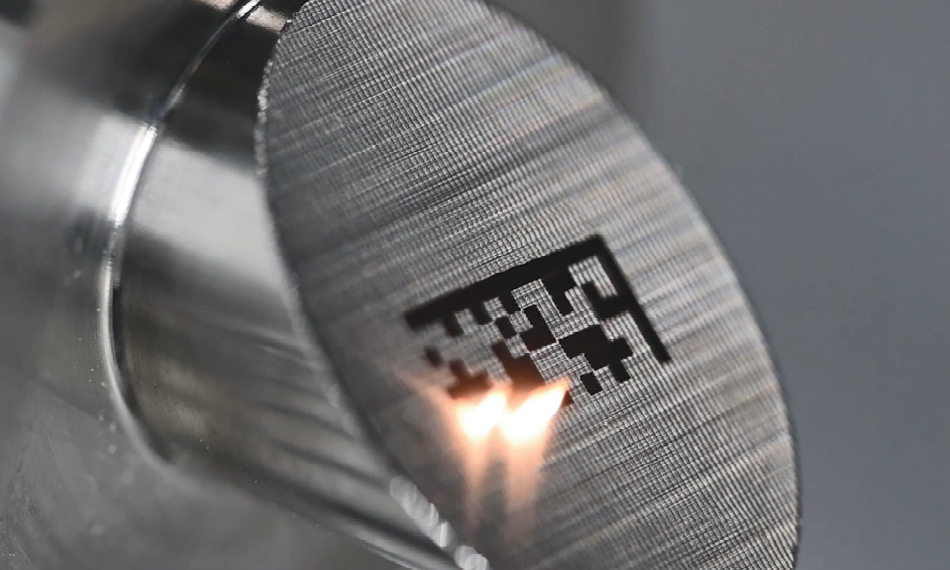

Laser engraving is often perceived as a simple 'burn and done' process. In reality, it is a complex interplay of photonics and thermodynamics. As a laser technician operating 50-watt fiber laser systems daily, I manipulate pulse frequency, speed, and power to alter the surface chemistry of metals, creating markings that range from subtle annealing to deep excavation.

Annealing vs. Engraving: The Stainless Steel Spectrum

On stainless steel thermos flasks, we often use a technique called 'annealing'. By defocusing the laser slightly and using low speed with high frequency, we heat the metal surface without vaporizing it. This induces an oxidation layer that appears black. The result is a smooth, dark mark that is perfectly flush with the surface. This is ideal for medical or food-grade items because there are no crevices to trap bacteria.

True engraving, on the other hand, involves vaporization. We focus the beam to its tightest spot size (often 0.05mm) and blast away the material. This creates depth. On a high-end brass pen barrel, we might engrave to a depth of 0.3mm and then fill the recess with an oxidizing agent to create a classic blackened look. This provides a tactile experience—your thumb can feel the logo.

The Aluminum Anomaly

Anodized aluminum behaves differently. The laser ablate the thin oxide layer (the colored part) to reveal the white/silver aluminum beneath. The contrast here is purely based on the difference between the anodized color and the raw metal. You cannot 'blacken' aluminum with a standard fiber laser; you can only whiten it. This is why we advise clients that a white logo on a silver pen will be invisible. Contrast is key.

Frequency and Hatching Strategies

The 'hatch' is the pattern the laser follows to fill a solid shape. A simple unidirectional hatch can leave banding lines. We use a cross-hatch strategy—0 degrees, then 90 degrees—to ensure a uniform finish. For larger logos, we might employ a 'wobble' function, where the beam spirals microscopically along the path, smoothing out the edges and reducing the jaggedness that can occur with vector files.

Mastering these parameters allows us to turn a generic metal item into a piece of precision-engineered branding. It is not just about putting a name on a product; it is about permanently altering the material to carry your identity.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.