One of the most confusing aspects of corporate gift procurement is the "Sum of Parts" paradox. A buyer will ask:

- "The MOQ for the pen is 50."

- "The MOQ for the notebook is 50."

- "So why is the MOQ for the Gift Set (Pen + Notebook) 200?"

From a fulfillment center perspective, a Gift Set is not just two products. It is a Manufacturing Assembly Project.

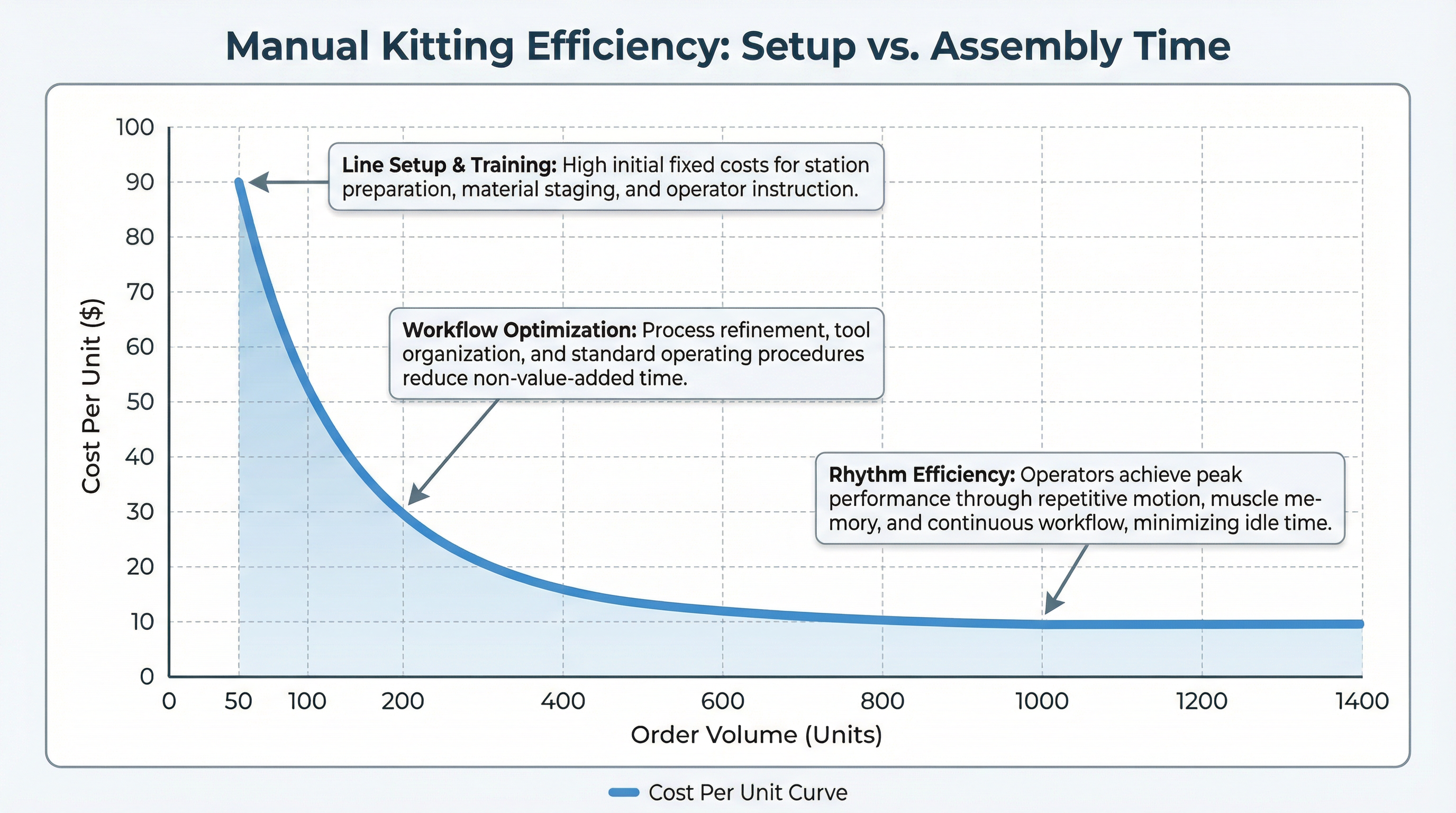

This article breaks down the hidden labor costs of "Kitting" that drive up Minimum Order Quantities for gift sets.

[Image blocked: Manual Kitting Efficiency: Setup vs. Assembly Time]

The "Assembly Line" Setup

When you order loose pens, we just pick a box off the shelf and ship it. When you order a Gift Set, we have to build a temporary assembly line.

The Process for 50 Gift Sets:

- Unpack: Remove 50 pens from their individual sleeves (Labor).

- Unpack: Remove 50 notebooks from their shrink wrap (Labor).

- Fold: Erect 50 flat-packed gift boxes (Labor).

- Insert: Place the foam inlay (Labor).

- Arrange: Position the pen and notebook precisely (Labor).

- Close & Sleeve: Seal the box and apply a belly band (Labor).

- Repack: Place the 50 gift sets into a master carton (Labor).

The Efficiency Problem: Setting up this workflow—clearing tables, training staff on the specific arrangement, and printing labels—takes about 2 hours.

- If we do this for 50 sets, the setup cost per unit is RM 5.00.

- If we do this for 200 sets, the setup cost per unit drops to RM 1.25.

The "Human Error" Buffer

In manual assembly, mistakes happen. A worker might scratch a pen while inserting it into the foam. A box might tear during folding.

For a run of 1,000 sets, a 1% defect rate is manageable. For a run of 50 sets, if 2 boxes are damaged, we might not have spares, and the order is short. Therefore, for small kitting orders, we must charge a "Risk Premium" or enforce a higher MOQ to ensure we have enough buffer stock to deliver a perfect order.

Strategic Advice for Buyers

If you need a small volume (e.g., 50 VIP sets) but want to avoid the high "Kitting MOQ":

-

DIY Assembly: Order the pens, notebooks, and empty boxes separately. Have your interns or admin team assemble them in the office. You save the factory labor cost and the high MOQ requirement.

-

Standard "Pre-Kitted" Sets: Choose a supplier's existing "Ready-to-Go" gift set. These are often pre-assembled during the off-season, so the MOQ is lower (often just 10–20 sets) because the labor cost has already been sunk.

Summary

Kitting is not just "putting things in a box." It is a labor-intensive service. Understanding the Setup vs. Assembly curve helps you decide when to pay for the service and when to do it yourself.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.