Nothing damages a corporate brand image faster than a team of employees wearing faded, mismatched uniforms. Imagine walking into a bank where the tellers' oncebright corporate blue shirts have faded to a dull greyish-purple. It subconsciously signals neglect and lack of attention to detail. As a QC manager who has rejected countless batches of fabric, I know that 'color fastness' is not just a buzzword—it's a measurable technical specification. The gold standard for testing this is ISO 105-C06: Textiles — Tests for colour fastness — Part C06: Colour fastness to domestic and commercial laundering.

Understanding the Test Method

ISO 105-C06 is not a single test but a series of test conditions (A to E) that simulate different washing severities. It is designed to predict how a fabric will behave after multiple wash cycles. The test involves washing a specimen of the fabric in contact with adjacent fabrics (usually a multifiber strip containing wool, acrylic, polyester, nylon, cotton, and acetate) in a specific detergent solution at a controlled temperature and mechanical agitation.

- Test A (40°C): Simulates mild domestic washing. Suitable for delicate fabrics.

- Test B (50°C): Simulates medium domestic washing.

- Test C (60°C): Simulates severe domestic washing or mild commercial laundering. This is the standard for most corporate uniforms (polos, shirts).

- Test D & E (Higher temps/chemicals): For industrial laundering, often used for medical scrubs or heavy-duty workwear.

Crucially, the test can include sodium perborate (a bleaching agent) to simulate the effect of modern detergents that contain oxygen bleach. The presence of steel balls in the test canister simulates the mechanical abrasion of a washing machine.

Interpreting the Grey Scale Ratings

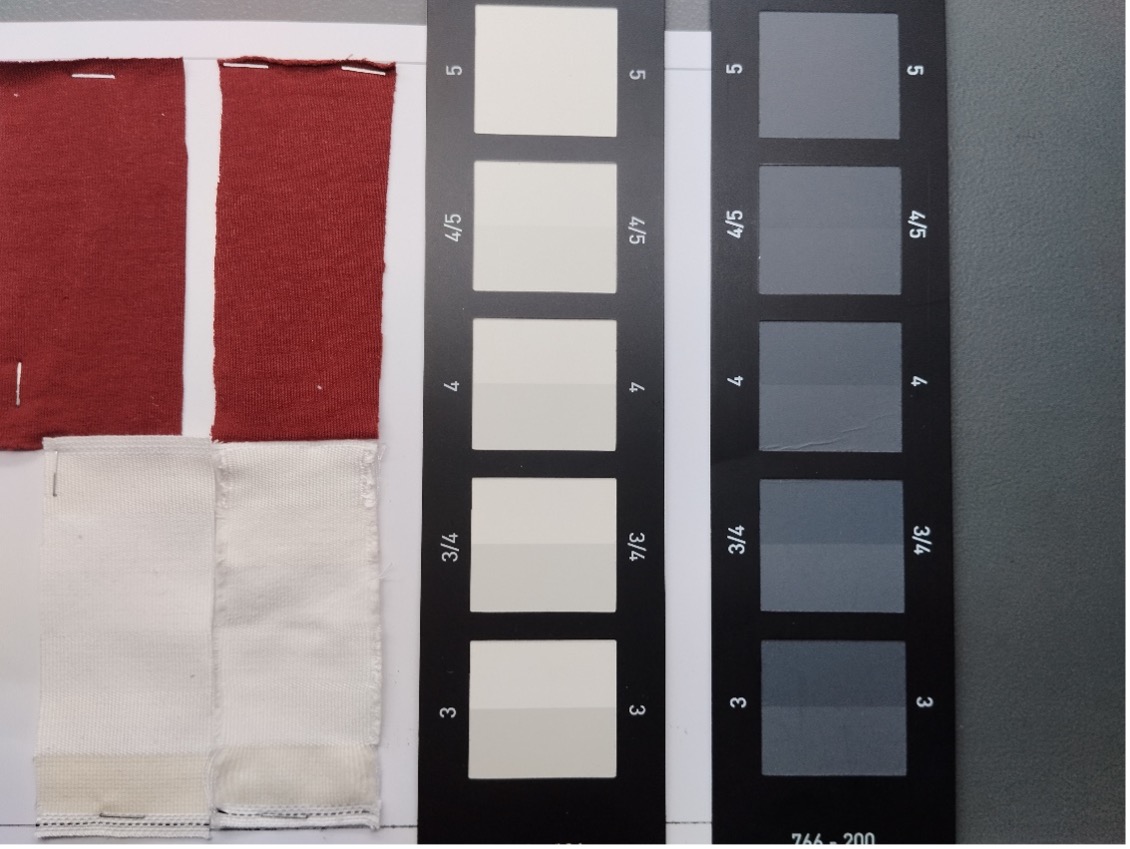

The results are reported using a Grey Scale, ranging from 1 (poor) to 5 (excellent). This is a visual assessment performed by trained technicians under controlled lighting (D65 light source).

- Color Change: How much did the original fabric fade? A rating of 5 means no change. A rating of 1 means significant fading.

- Staining: How much did the dye bleed onto the adjacent multifiber strip? This checks if the dye will ruin other clothes in the same wash load.

For corporate uniforms, we typically require a minimum rating of 4 for both color change and staining. A rating of 3 might be acceptable for low-cost promotional t-shirts, but for a daily-wear uniform, it will look old within a month.

The Impact of Sweat (ISO 105-E04) on Uniforms

While ISO 105-C06 covers washing, another critical factor for uniforms in Malaysia's tropical climate is sweat. ISO 105-E04 tests for color fastness to perspiration. Human sweat is acidic (or sometimes alkaline), and it can react with certain dyes, causing them to migrate or change color.

We often see 'collar discoloration' where the fabric touching the neck fades faster than the rest of the shirt. This is a combination of sweat and friction. A fabric might pass the washing test (C06) but fail the perspiration test (E04). Therefore, for uniforms worn outdoors (e.g., delivery riders, construction supervisors), we mandate passing both C06 and E04 with a minimum rating of 4.

Corrective Actions for Failed Batches

What happens if a batch fails the test? Is it a total loss?

- Re-Washing (Stripping): Sometimes, the failure is due to excess unfixed dye on the surface. Running the fabric through a high-temperature 'reduction clearing' wash can remove this loose dye. The fabric is then re-tested. This often improves the staining rating but might slightly lighten the overall shade.

- Fixing Agents: Applying a cationic fixing agent can improve wet fastness. However, this can sometimes affect the hand feel (making it stiffer) or the shade (making it duller).

- Downgrading: If the fabric cannot be saved for the primary client, it might be sold as 'B-grade' stock for less critical applications, or dyed black (which covers most sins).

Real-World Supply Chain Incident: The 'Red Polo' Disaster

I recall a project for a major logistics company that ordered 5,000 red polo shirts. The pre-production sample passed the lab test with a rating of 4-5. However, the bulk fabric production was rushed. The dyeing factory shortened the 'soaping' process—the final wash step that removes unfixed dye from the fiber surface.

When the shirts arrived, they looked perfect. But after the first wash by the employees, the red dye bled profusely, turning the white collars pink. We sent a random sample from the bulk lot to the lab. The result? ISO 105-C06 Staining Rating: 1-2.

The Lesson: A 'passed' lab report on a sample is not enough. You must implement random lot testing on the actual bulk fabric before cutting and sewing begins.

Drafting a Waterproof QC Contract Clause

To protect your company, your purchase order (PO) must be specific. Do not just say "good quality." Use this standard clause:

"All fabric must be tested by an accredited third-party lab (e.g., SGS, Intertek, Bureau Veritas) according to ISO 105-C06 A2S. Minimum requirement: Grade 4 for Color Change and Grade 4 for Staining on all fibers. Supplier must submit the original lab report for the bulk lot before shipment. Failure to meet these standards gives the buyer the right to reject the entire shipment at the supplier's cost."

2025 Trends in Color Fastness

With the push for sustainability, we are seeing more use of natural dyes and recycled polyester (rPET).

- rPET Challenges: Recycled polyester can sometimes hold dye differently than virgin polyester due to impurities, leading to batch-to-batch color variation. Procurement managers need to be aware of this and perhaps widen their color tolerance slightly (Delta E < 1.2 instead of < 1.0) or insist on cationic dyeable polyester for better fastness.

- Solution Dyeing: For large orders, we recommend 'Solution Dyeing' (or Dope Dyeing), where the pigment is added to the polymer melt before the fiber is extruded. This results in color fastness ratings of 5+, as the color is integral to the fiber, not just on the surface. It uses less water and energy but requires higher Minimum Order Quantities (MOQs).

By understanding ISO 105-C06, you move from subjective complaints ("it looks faded") to objective, enforceable quality standards, protecting your brand's visual integrity.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.