When procurement managers order a "Corporate Gift Set" (e.g., a box containing a notebook, a pen, and a power bank), they usually calculate the lead time based on the "Critical Path Method."

They ask: "Which item takes the longest?"

- Notebook: 15 Days

- Pen: 10 Days

- Power Bank: 12 Days

They conclude: "The lead time is 15 days."

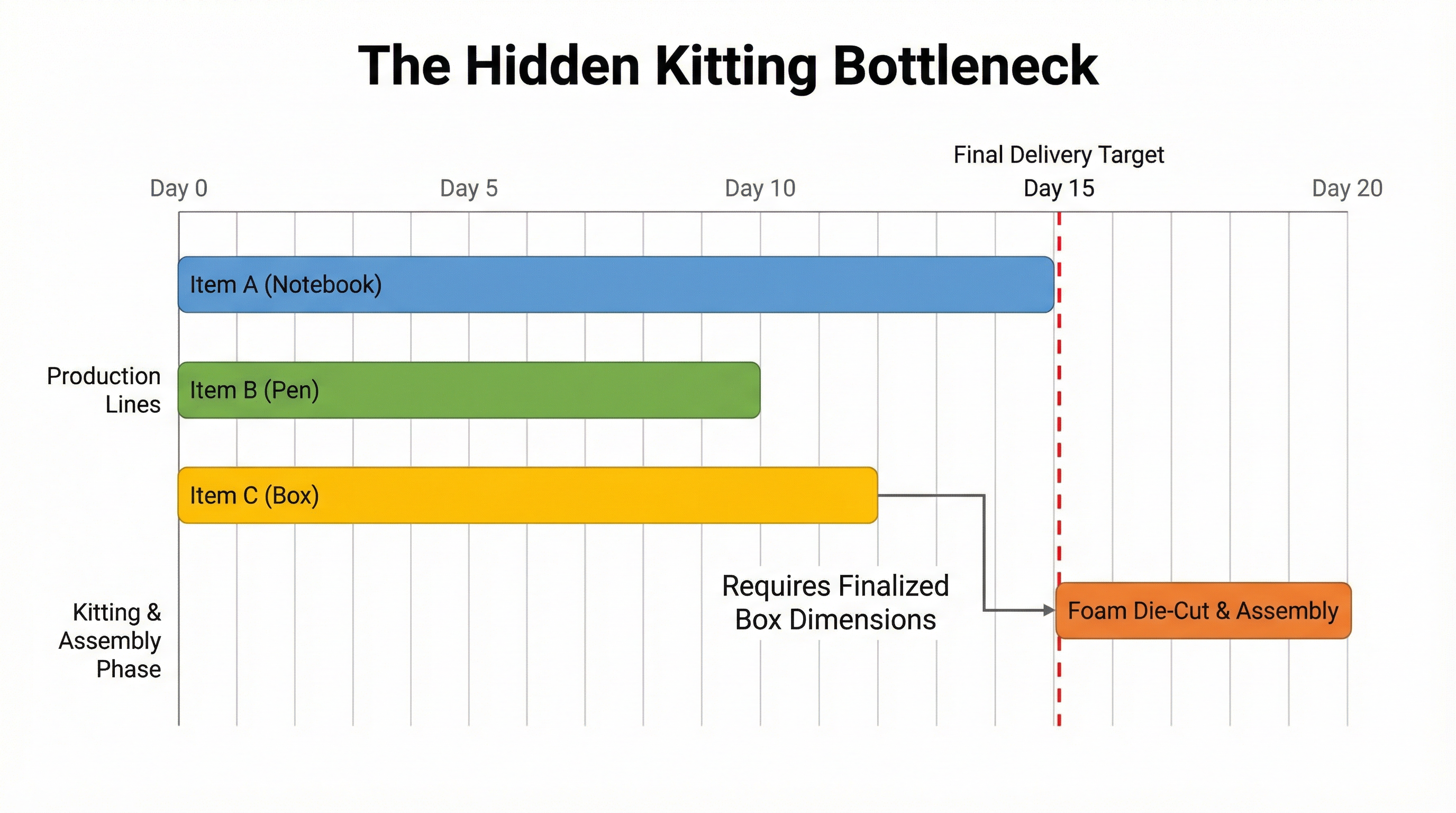

As a Factory Manager, I can tell you this calculation is mathematically correct but operationally disastrous. It ignores the final, most labor-intensive step: Kitting & Assembly.

The "Sequential Assembly" Reality

You cannot start assembling the gift set until all items are physically on the table. If the notebooks arrive on Day 15, the assembly line starts on Day 16.

But here is the catch: Assembly is not just "putting things in a box." For premium gift sets, it involves:

- Foam Die-Cutting: We need to cut the EVA foam insert to fit the exact dimensions of the final mass-produced items. We cannot cut the foam based on the sample, because mass production tolerances might vary by 1-2mm. If we cut too early, the items won't fit snugly.

- Manual Labor: Placing 1,000 pens into 1,000 foam slots, cleaning the dust off 1,000 black boxes, and applying 1,000 belly bands is a manual process. A team of 5 workers might only pack 300 sets a day.

The Math: 15 Days (Production) + 5 Days (Kitting) = 20 Days Total.

[Image blocked: Gantt chart showing how the 'Kitting & Assembly' phase is a separate block that only starts after the longest item is finished, extending the total timeline.]

The "Space Constraint" Risk

Another hidden factor is physical space. A factory might have the capacity to produce 5,000 notebooks, but it might not have the floor space to lay out 5,000 open gift boxes for assembly.

This forces us to run "Batch Assembly":

- Day 16: Assemble 1,000 sets -> Pack -> Ship.

- Day 17: Assemble next 1,000 sets.

If you need all 5,000 sets delivered to your event hall at 9:00 AM on Monday, this batching process becomes a logistical nightmare.

How to Plan for the "Kitting Gap"

- Add a "Kitting Buffer": Always add 3–5 days on top of your longest item's lead time specifically for assembly.

- Approve the "Die-Cut Line" Early: Don't wait for the items to arrive. Ask the factory to send you the "Die-Cut Line" (digital blueprint of the foam) for approval while production is running.

- Consider "Flat-Pack" Delivery: If you are truly out of time, ask if the boxes can be delivered "flat" (unassembled) and the items in bulk. You can then hire temporary staff to assemble them at your office. It's messy, but it saves 3 days.

In the world of gift sets, the product is not finished when it comes off the machine. It is finished when it sits securely in its foam nest. Ignoring this final step is the most common reason for lead time [blocked] overruns.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.