In corporate procurement, a common friction point arises when a marketing team requests a "unique shape" for a product—such as a power bank in the shape of a company mascot or a specifically dimensioned water bottle—and is shocked by the sudden jump in Minimum Order Quantity (MOQ) from 100 units to 3,000 units.

This article explains the technical and financial mechanics behind this jump, specifically focusing on the Custom Mold Opening process.

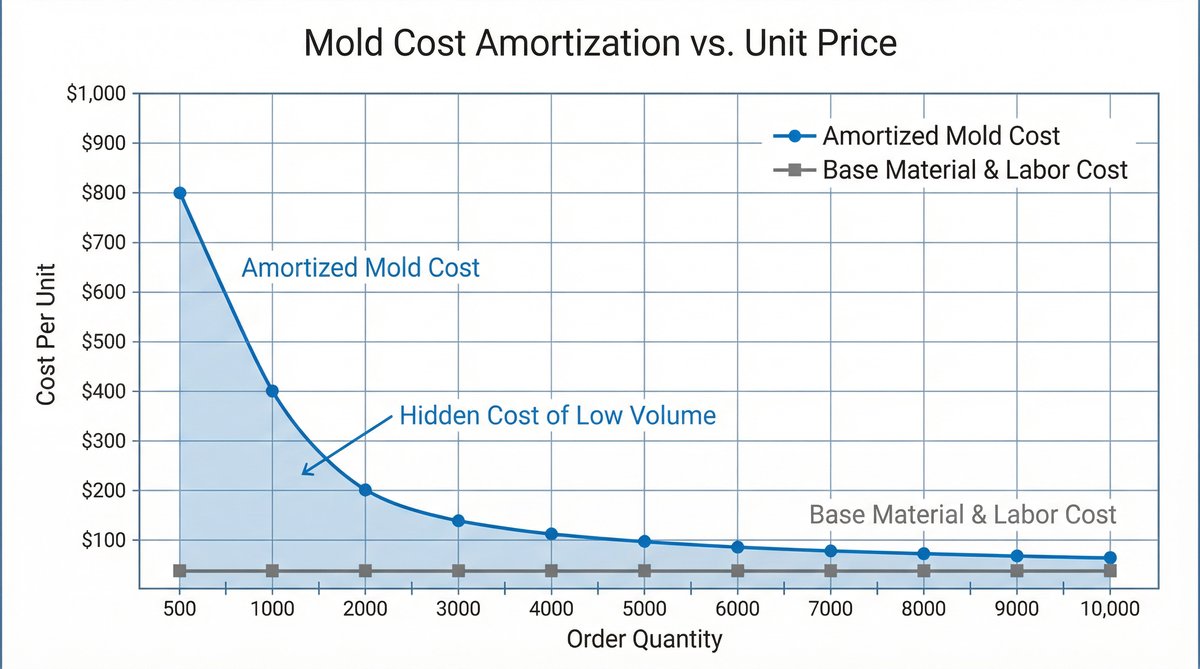

[Image blocked: Mold Cost Amortization vs. Unit Price]

The Economics of Tooling Amortization

The primary driver of high MOQ for custom shapes is the Mold Cost.

A steel injection mold for a plastic product typically costs between RM 5,000 and RM 20,000 depending on complexity. This is a fixed, upfront capital expenditure (CapEx) that must be paid before a single unit is produced.

- Scenario A (Low Volume): If you order 100 units, the mold cost alone adds RM 50.00 to each unit (RM 5,000 / 100). This makes the unit price unmarketable.

- Scenario B (High Volume): If you order 5,000 units, the mold cost amortizes to just RM 1.00 per unit.

Therefore, factories set an MOQ (e.g., 3,000 units) to ensure that the amortized tooling cost does not inflate the unit price beyond what the market will bear.

Machine Setup and Purging Waste

Beyond the mold itself, the injection molding process requires significant setup.

- Mounting the Mold: It takes 2–4 hours for a technician to crane the heavy steel mold into the injection machine, align it, and heat it to operating temperature.

- Purging Material: When switching colors or materials (e.g., from black ABS to white PP), the machine must be "purged." This involves running raw plastic through the screw to clean it, creating kilograms of waste material.

If a factory runs a 500-unit order, the time spent setting up and purging might exceed the time spent actually molding the products. This "downtime ratio" is financially unsustainable, hence the requirement for longer production runs (higher MOQ).

The "Open Mold" Alternative

For clients who cannot meet the 3,000-unit threshold, the industry alternative is to use an "Open Mold" (Public Mold).

These are pre-existing designs owned by the factory. You cannot change the shape, but you can customize the color and print your logo. Because the mold cost has already been paid for by previous orders (or the factory's own investment), the MOQ drops significantly—often to 100–500 units.

Summary for Procurement

When a stakeholder demands a "fully custom shape," they are implicitly signing up for a 3,000+ unit commitment. If the volume requirement is lower, the conversation must shift to "customizing an existing shape" to avoid the prohibitive economics of new tooling.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.