In my years managing production lines for corporate gift manufacturing, the most common friction point I encounter is the "Linear Time Fallacy."

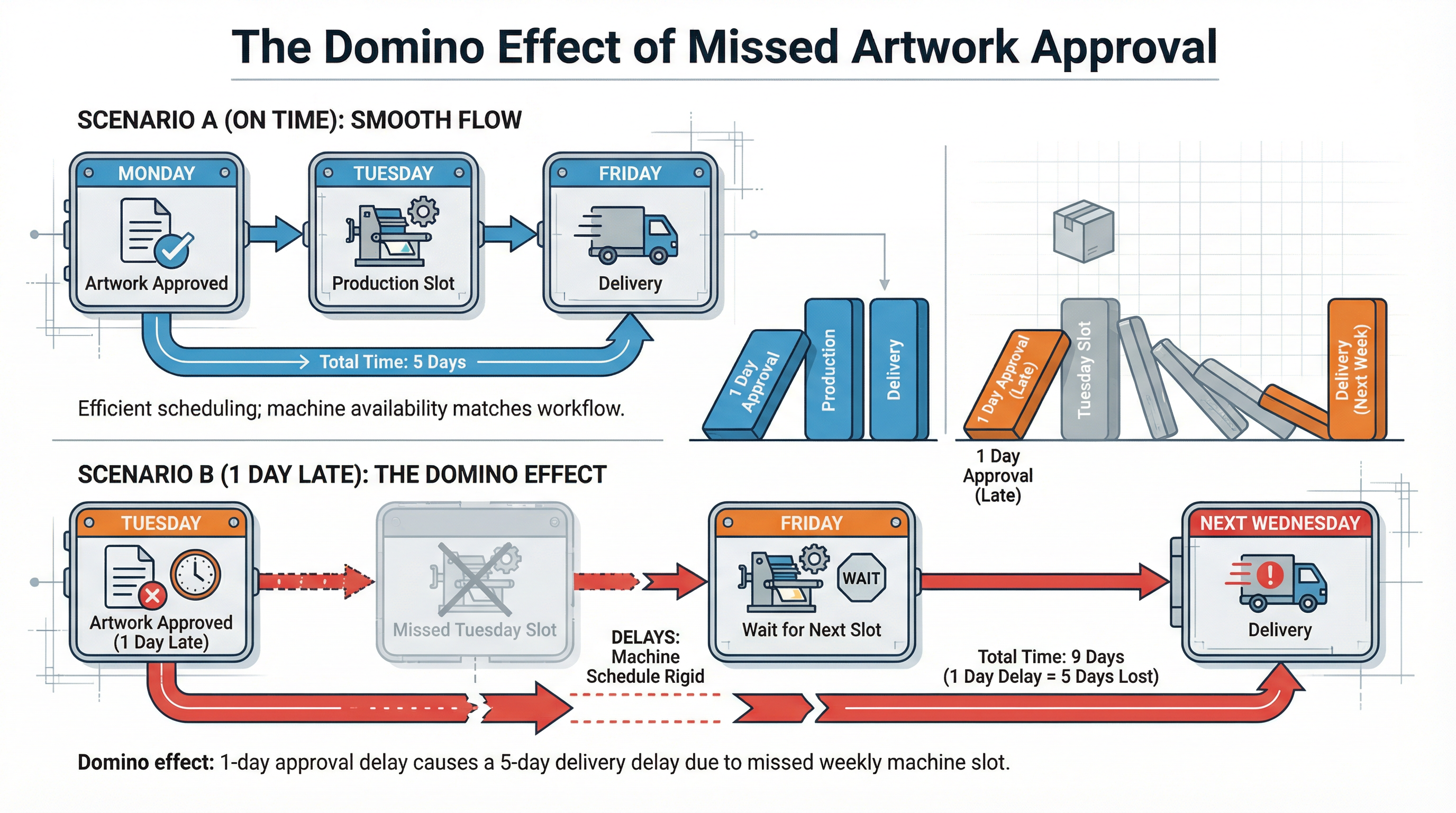

Procurement teams often assume that production is a linear, fluid process: if they delay the artwork approval by one day, the delivery will simply be delayed by one day.

In practice, this is almost never true. Manufacturing does not run on a continuous, on-demand stream for every single client. It runs on slots and changeovers.

The Concept of "Production Slot Loss"

Factories operate on rigid schedules to maximize efficiency. We group similar jobs together to minimize "changeover time"—the downtime required to clean machines, change inks, and recalibrate alignment for a new product type.

For example, our UV printing line might be scheduled to run "Black Notebooks" on Monday and Tuesday, and "White Power Banks" on Wednesday and Thursday.

If your order is for Black Notebooks, and you are scheduled for the Tuesday afternoon slot, we need your "Final Artwork Approval" by Tuesday morning at the latest.

The Domino Effect

If you confirm the artwork on Tuesday evening instead (just a few hours late), you haven't just missed the deadline; you have missed the slot.

By Wednesday morning, the machine has already been stripped, cleaned, and re-setup for White Power Banks. We cannot simply "squeeze you in" because the machine is physically incapable of printing your notebooks without another 4-hour changeover.

Your order now has to wait until the next time the machine is scheduled for Black Notebooks, which might be next Monday.

The Result: A 5-hour delay in approval results in a 5-day delay in production start.

[Image blocked: Diagram showing how a 1-day delay in artwork approval causes a missed production slot, leading to a multi-day delivery delay.]

The "Queue Jumping" Risk

Another factor that clients rarely see is the queue system. When you miss your slot, you don't just slide to the next immediate opening. You go to the back of the line for the next available slot.

If another client confirmed their artwork on time while you were deliberating, they take the priority. In peak seasons (like pre-CNY or Year-End), missing a slot can sometimes mean missing the entire production window for that week, as capacity is booked at 110%.

How to Mitigate This Risk

- Ask for the "Cut-Off Time": Don't just ask for the lead time. Ask your supplier: "When is the absolute latest I can approve the artwork to catch this week's production run?"

- Pre-Approve the Concept: If your internal stakeholders are slow, get them to approve the concept and placement early. Leave only the final variable (e.g., the exact name list) for the last minute.

- Understand the "Changeover": If you are ordering a highly customized item (e.g., a custom-dyed fabric), the changeover penalty is even higher than for standard printing. Missing a dyeing slot can delay fabric production by 2 weeks.

In the world of manufacturing, time is not continuous; it is quantized into slots. Respecting the slot boundaries is the single most effective way to ensure your lead time [blocked] remains on track.

Planning a Custom Notebook Project?

Check our detailed supplier capabilities guide to see what's feasible for your budget and timeline.